What Is CTP Plate

May 24, 2024

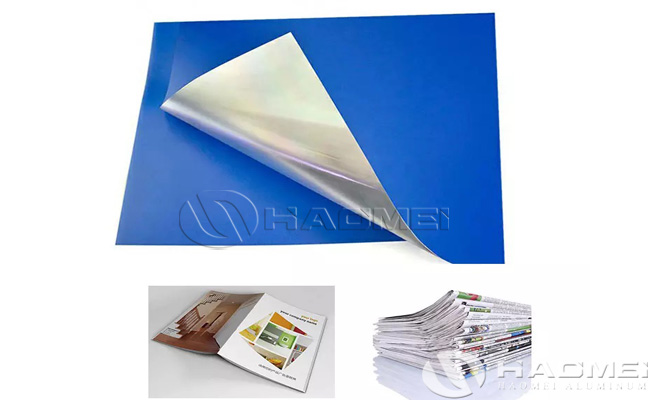

A CTP (Computer-to-Plate) plate is a digitized printing plate used for lithography in the printing industry. Compared with the traditional CTF (Computer-to-Film) process, CTP technology directly transfers the digitized printing image to the printing plate, eliminating the step of making film and improving printing efficiency and quality. This technology eliminates the need for photographic film and its processing chemicals, reducing the film exposure processing, plate retouching, plate tanning and other links, reducing costs, saving time and space, while the image transfer quality significantly improved, reducing environmental pollution.

The specifications of CTP plates can vary according to different manufacturers and models. The following is a general range of common CTP plate specifications:

Size: Normally, the standard size of CTP plates is 1030mm x 800mm, 800mm x 1030mm, 860mm x 660mm, 660mm x 860mm, etc. Of course, there are other non-standard sizes of CTP plate.

Thickness: The thickness of CTP plates usually ranges from 0.15mm to 0.40mm, which may vary with different press models and printing needs.

There are types of CTP plate products in the market. These products are based on CTP technology and are used for direct plate making in the printing industry.The main products of CTP plates include:

Thermal CTP Plate is a common type of CTP Plate, which is covered with a heat-sensitive coating that is used to form an image directly on the plate by means of the thermal laser or thermal head of the CTP equipment, and then curing the image by chemical treatment.

UV CTP plate is another common type of CTP plate, which is coated with a layer of UV-sensitive coating, and the image is formed on the plate by UV laser, and then the image is cured by UV light.

- Water-based CTP plate:

Water-based CTP plate is an environmentally friendly CTP plate that uses a water-based coating instead of traditional chemical solvents to reduce the impact on the environment.

- Laser CTP plate:

Laser CTP version is the use of laser technology to form images directly on the layout of a CTP version of the type of high-precision and high-speed features.

The development of CTP technology makes the printing industry more digitalized, automated and environmentally friendly, improves printing efficiency and quality, and gradually replaces the traditional CTF process.CTP plates are widely used in the printing industry in the fields of book printing, packaging printing, commercial printing and so on.

Nydia

Nydia

Sales Manager

Sales Manager