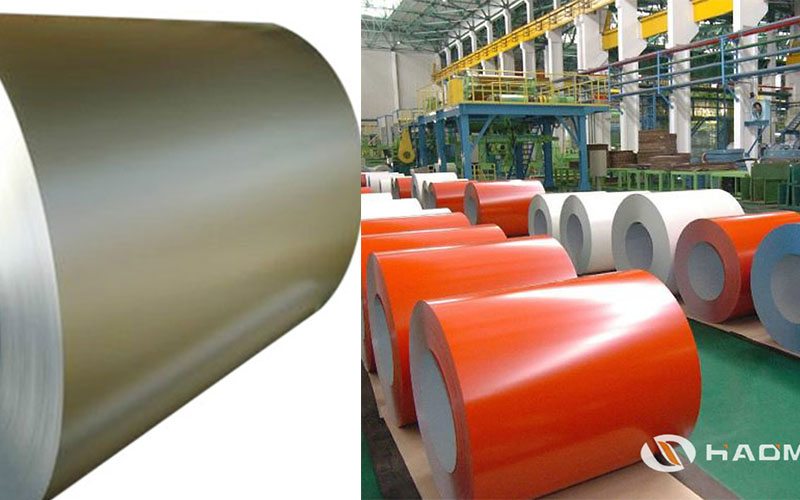

Requirements of Raw Material for Color Coated Aluminum Coil Rolls

The color coated aluminum coil is obtained by further processing of plain aluminum coil rolls. Requirements of its raw material are as below. 1. It can contain up to 0.20% zirconium and titanium. 2. The elemental properties of the combination are expressed as the highest percentage unless a range or minimum value is listed. 3. With a purpose to decide …

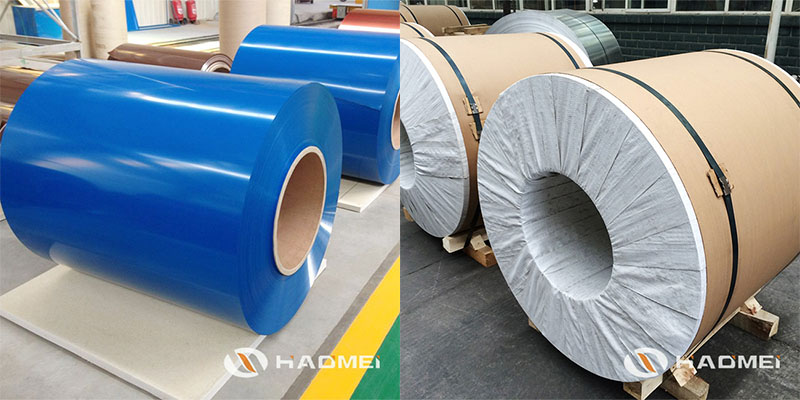

How to Maintain Color Coated Aluminum Coil

The color coated aluminum is a composite material containing both aluminium and mechanics, which endows it with excellent dyeing property and corrosion resistance of mechanism as well as light wight, easy processing and high strength of aluminium. In particular, well-treated pvdf color coated aluminum coil lasts as long as 30 years. These advantages make colour coated aluminium coil the top …

Roller Coating Process of PVDF Color Coated Aluminum Coil

The roll coating process is an effective method to coat color coated aluminum with organic protective coatings. As a continuous and highly automated process, it helps to produce pvdf color coated aluminum coil rolls of better consistency than those from post-coating methods. Typical coating line systems require aluminium substrates of good moulding property, satisfying scratch-proof ability, beautiful appearance, excellent weather …

PVDF Color Coated Aluminum Coil Manufacturers

In the past years the color coated aluminum industry in China has developed rapidly. No matter how many factories there are, some problems still exist with color coated coil manufacturers, including coil thickness, product class, industry normalization and production line stability. Restricted by backward technology, few manufacturers in China are able to supply pvdf color coated aluminum coil of thickness …

3003 PVDF Color Coated Aluminum Coil for Beverage Cans

3003 pvdf color coated aluminum coil is a regular product for beverage cans. It has good corrosion resistance, workability, printing ability and light weight. 3003 aluminum coil contains a certain content of manganese that is known for excellent corrosion resistance. As the most widely applied anti-rust aluminum coil, 3003 is not suitable for heat treatment, thus cold processing is the …

Nydia

Nydia

Sales Manager

Sales Manager