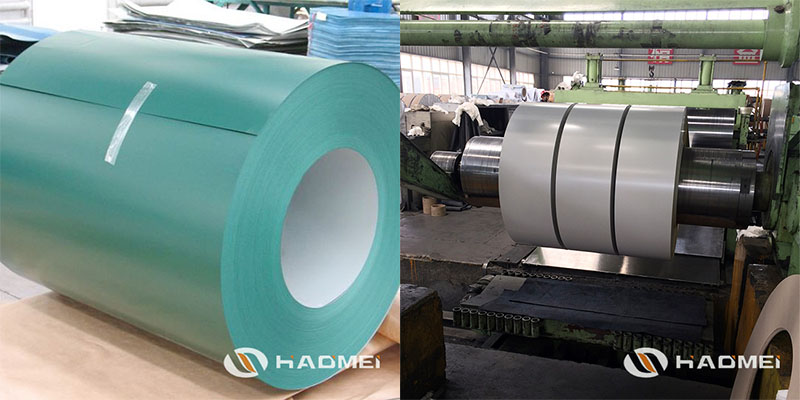

Painted Aluminum Trim Coil

The painted aluminum trim coil are packaged in rolls, so they can also be called color coated aluminum trim coils. The surface of the painted aluminum coil is treated with fluorocarbon coloring and special processes, such as metal drawing, engraving patterns, etc., have a very decorative effect. So the aluminum trim coil color coated is widely recognized by modern families. Color …

5052 painted aluminum coil features and application

The features of 5052 painted aluminum coil cover those of 5052 coil but prove to be more than them. 5052 alloy aluminum coil is one of the commonly used color-coated aluminum coil rolls. It has good forming and processing performance, corrosion resistance, candleability, fatigue strength and medium static strength. Its main element is magnesium, and the magnesium content is between …

3004 painted aluminum coil for roofing

The application of 3004 painted aluminum coil guangzhou in roofing is based on changing requirements of modern architecture industry that pursues economy, environmental protection, durability, and easy maintenance. At present, more and more shopping malls, exhibition halls, workshops, and civil houses use aluminum-manganese alloy as roofing and exterior wall materials. Commonly used grades are 3003 and 3004. At present, there …

Why is pvc used in painted aluminum coil

Aluminum coil painted materials requires the use of special coatings to ensure excellent adhesion and protection. Ordinary paints, such as polyurethane paint, acrylic paint, zinc-rich primer, etc., are difficult to adhere to the metal surface, and cannot achieve the effect of anti-corrosion decoration. Dispersing polyvinyl chloride in a liquid plasticizer, plasticizing it into a plastisol, and adding emulsion (a kind …

Solution to Gloss Problems of Painted Aluminum Coil

As a composite material with multiple chemical elements, color painted aluminum coil rolls are extensively applied in various industries. However, a typical problem complained by not a few users is that color coated aluminium materials they use are lacking in enough gloss, which makes them less attractive than they actually should be. Generally there are two reasons for this: process problem …

Nydia

Nydia

Sales Manager

Sales Manager