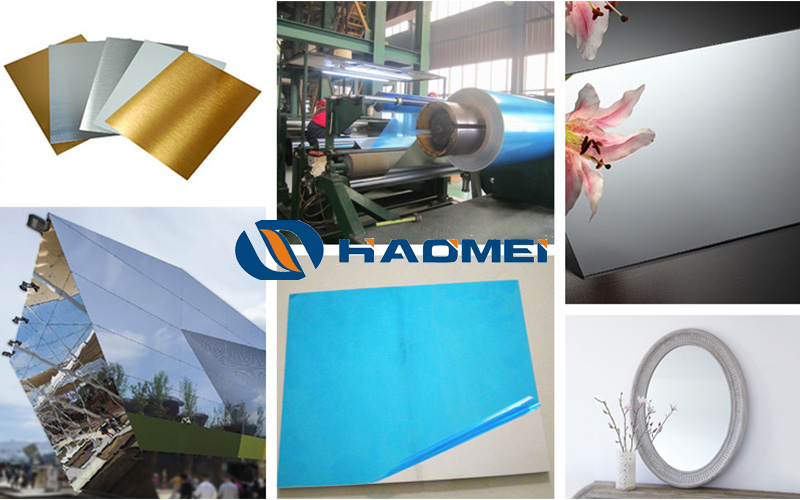

0.4mm mirror finish anodized aluminum sheet features and price

0.4mm mirror aluminum sheet is among regular specifications of mirror finish anodized aluminum sheet pieces. Other thickness include 0.6mm and 0.8mm etc. Its raw material comes from three series of aluminium sheets: 1xxx, 3xxx and 5xxx. 1050, 1060, 1070 and 1100 boast high purity, simple processes and low prices. The most popular 1xxx 0.4mm mirror aluminum sheet products are 1050 …

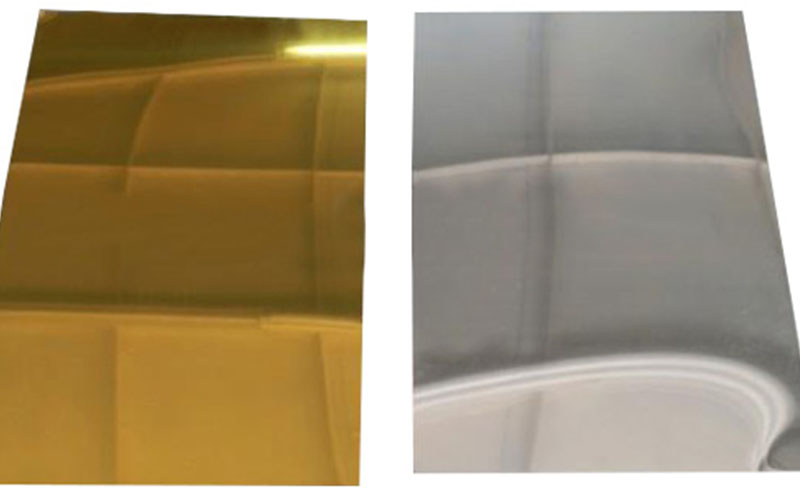

Mirror finish anodized aluminum sheet color and features

The mirror finish anodized aluminum sheet is obtained by placing an aluminum mirror sheet in a corresponding electrolyte as an anode, and performing electrolysis under specific conditions and an applied current. The aluminum sheet of the anode is oxidized and a thin layer of alumina is formed on the surface. A mirror finish anodized aluminum sheet is featured by strong …

Advantages of Mirror Finish Anodized Aluminum Sheet over Glass

The aluminum mirror sheet has won increasing popularity as a decorative metal material. Functioning similar to a glass, mirror finish anodized aluminum sheet covers a much wider scope of application. In comparison with glass, it has the following advantages. First, the mirror finish anodized aluminum sheet has a medium strength and a good tensile strength. This enables it to withstand …

How to Improve Purity of Oxide Film for Aluminum Mirror Sheets

The purity of oxide film plays a crucial role in deciding quality of aluminum mirror sheets. Some manufacturers supplies reflective aluminum sheet metal pieces as bring as mirrors, while others offer shiny aluminum sheet pieces that are not shiny at all. An impure oxide film makes a piece of mirror finish anodized aluminum sheet look like being covered with a …

Polishing Methods of Aluminium Mirror Finish Sheet

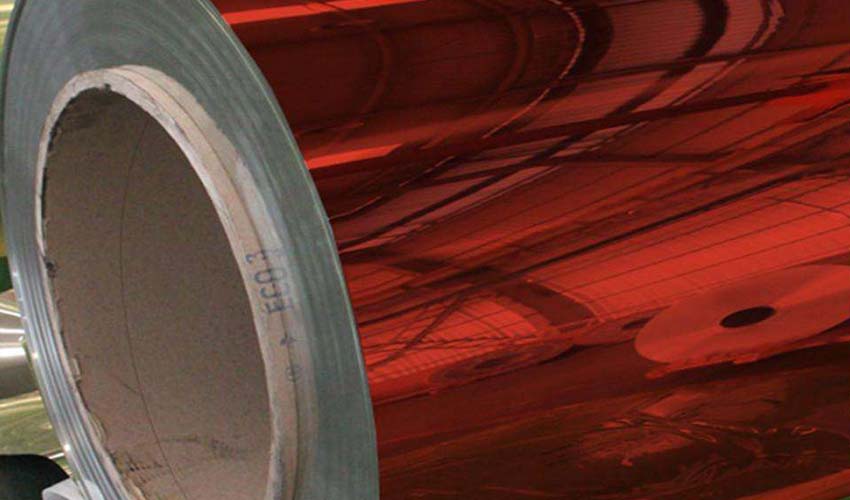

As known to all, aluminium mirror finish sheets are obtained by polishing aluminum substrates of given alloys and tempers. There are roughly three polishing methods: buffing, buffing&chemical polishing and electronic chemical polishing with the previous two polishing steps. Needless to say, the last method produces the highest quality. Each of the methods can be further divided in practice. Take buffing …

Anodizing of Mirror Finish Anodized Aluminum Sheet

Anodizing is an important step for improvement of aluminum sheet’s corrosion resistance and colors. The production of mirror finish anodized aluminum sheet can not avoid such a process, either. An anodized aluminum sheet is applied in products of high requirements about surface and service life. Take the aluminum mirror sheet for example. It’s usually processed into furniture panels, ceilings, curtain …

Mirror Finish Anodized Aluminum Sheet for Curtain Walls

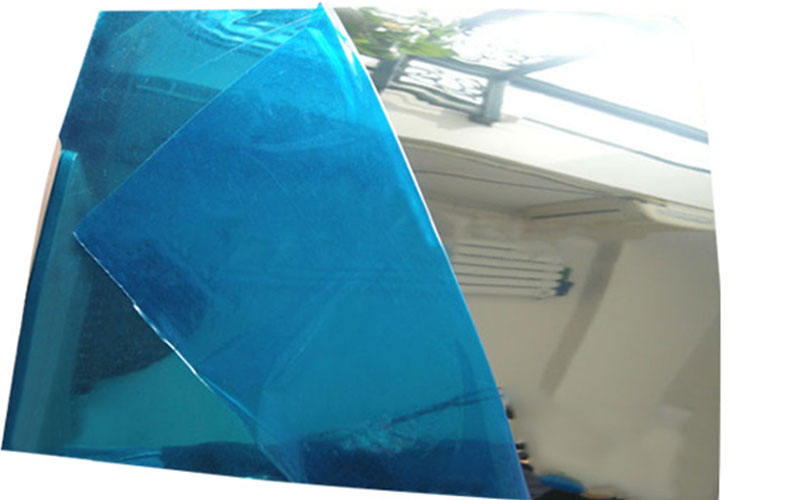

Main materials for curtain wall include stone, glass, plastic composite materials, aluminum panels etc. Raw material of aluminum panels can be further divided into plain aluminum sheet, color coated aluminum sheet and aluminum mirror sheet. The surface of mirror finish anodized aluminum sheet for curtain wall is very beautiful. The gloss is very high, and the color can be coated …

Mirror Finish Anodized Aluminum Sheet for Food Packing

Speaking of food packing, we would think of plastics, paper and aluminum foil, but few people would relate mirror finish anodized aluminum sheet to food packing. As a matter of fact, mirror anodized aluminum sheet takes up an even larger market in food packing. The reason why it rarely comes to our mind become it’s usually applied in packing of …

Mirror Finish Anodized Aluminum Sheet Maintenance 2

Aluminum mirror sheet refers to aluminium sheet taking on a mirroring effect. It has two types: polished aluminum mirror sheet and mirror finish anodized aluminum sheet. The latter is of better quality and performance. It covers a wide range of application in our daily life, such as exterior and interior decoration, home appliances, shells of digital products, kitchen utensils, tiny …

Mirror Finish Anodized Aluminum Sheet Maintenance 1

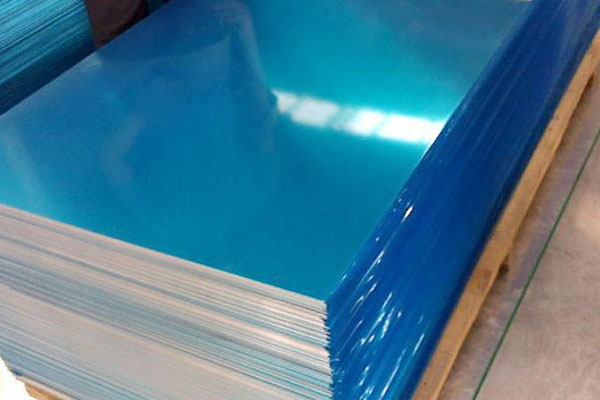

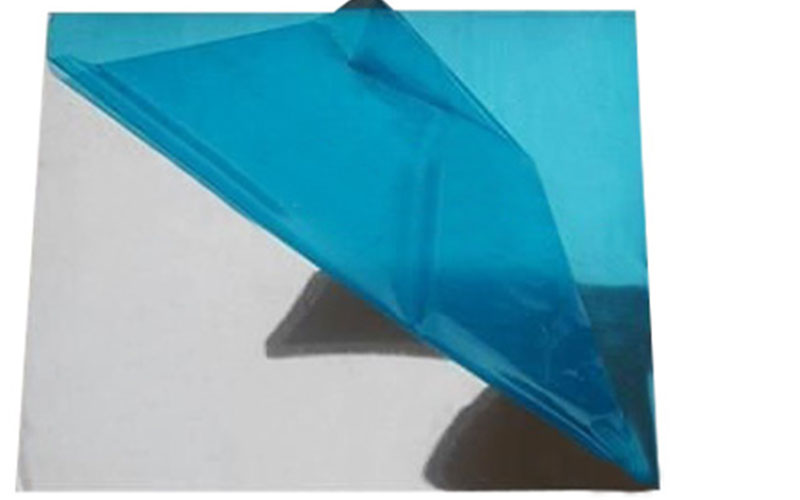

Semi-processed aluminium products plays an important role in our life. Take mirror finish anodized aluminum sheet for example. It serves as raw material at hour homes for items from furniture to wall panels. Then how to maintain the sheet effectively? 1. Do not tear off the protective film of a mirror finish anodized aluminum sheet product during installation, because accidental …

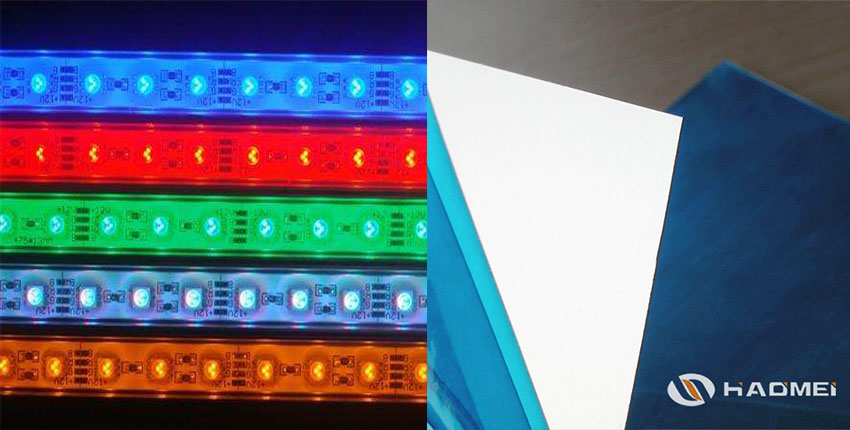

Features of Mirror Finish Anodized Aluminum Sheet for COB

An aluminum substrate serves as one of the most important component for LED lamps. The most suitable aluminum product for the substrate proves to be mirror finish anodized aluminum sheet, which is featured by good heat exchange, high reflectivity, convenient operation and low cost. The technology of electrically neutral thermal path is applied to the substrate of mirror anodized aluminum …

Mirror Finish Anodized Aluminum Sheet Used for Ornaments

Ornaments are ubiquitous in our daily life. Some of them are made of plastics. Some are of glass, and others are of metals, among which mirror finish anodized aluminum sheet proves to be a popular one. As an ornament usually takes up few weight of a whole item, the material for it must be as light as possible. Plastics is …

Nydia

Nydia

Sales Manager

Sales Manager