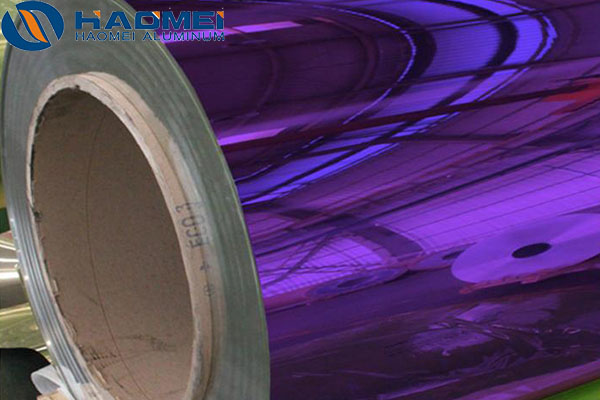

Color mirror aluminum sheet

Thanks to fast development in science and technology, the color mirror aluminum sheet comes into being and brings more beauty to our world. This sheet is actually a type of anodized aluminum sheet that has been colored, for anodizing proves to be the best method for coloring a mirror sheet. Different from a regular piece of mirror sheet, anodized sheets have …

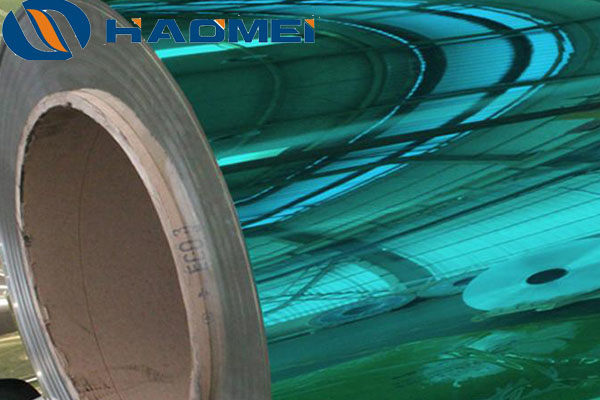

Mirror aluminum sheet 3003

Mirror aluminum sheet 3003 ranks middle by quality in all alloys of aluminium mirror sheets. It overshadows 1050, 1060, 1070 and 1100 in either hardness or corrosion resistance, but can not compete with 5005, 5757, 5052 and 5083 in the two aspects. 3003 mirror sheets are used extensively in solar reflective panels, light reflective covers and ornaments, interior decoration, exterior …

Polishing methods for polish mirror aluminum sheets

A polish mirror aluminum sheet is among the most widely applied ferrous metal. With fast economic development, it is more and more widely used in roofing, interior decoration and advertising. Generally there are two ways to polish a sheet: physical polishing and chemical polishing. Aluminum reflective sheet suppliers usually adopt the chemical method, which are further divided into four types. …

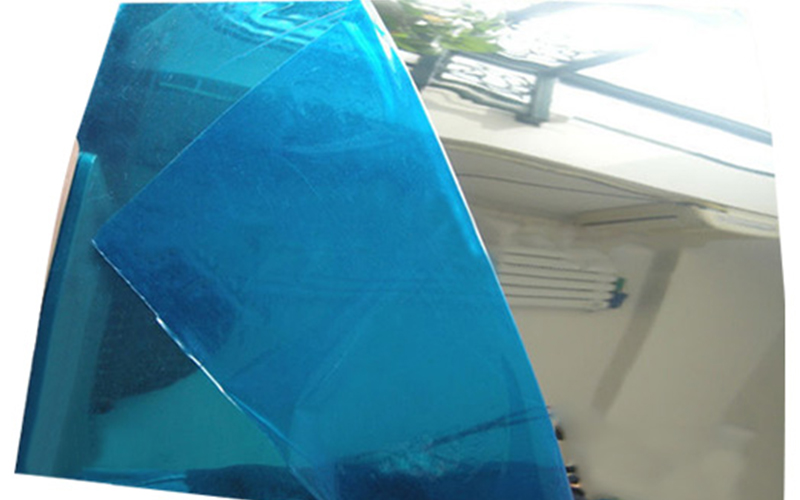

Types of mirror aluminum sheet film

There are two regular types of mirror aluminum sheet film: electrostatic film and PE textured film. The electrostatic film is a kind of non-adhesive film, mainly made of PE and PVC. It is protected by electrostatic adsorption of an aluminum sheet itself. It is generally used for the surface sensitive to adhesive or glue residue. It is mostly used for …

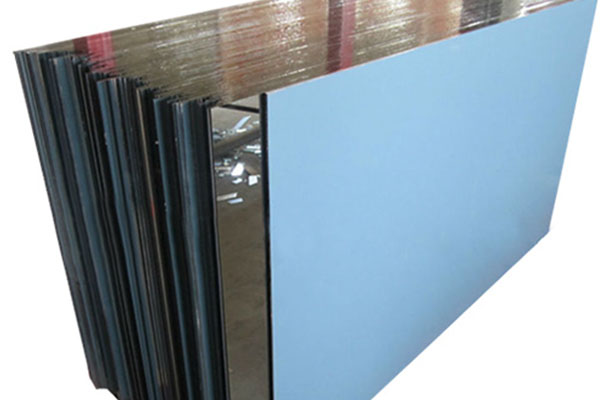

Mirror aluminum sheet plate features and usages

The mirror aluminum sheet plate is an extensively applied product in lighting, labeling and building decoration. It’s a piece of aluminum sheet taking on a mirroring effect. Different from a mirror, it’s much harder and more resistant to impact of shocks. Such a mirror aluminum sheet is obtained by rolling and polishing (mechanically or manually) in China, yet by rolling …

Nydia

Nydia

Sales Manager

Sales Manager