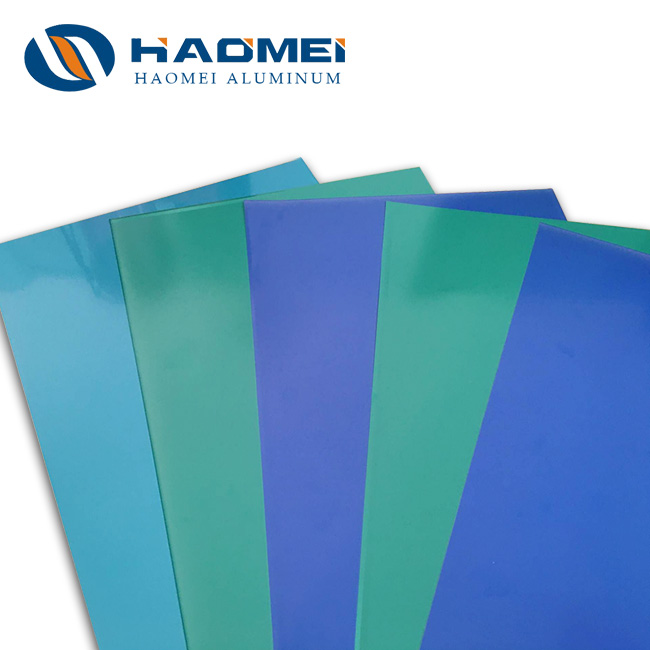

CTP Thermal Plate

Features of CTP Thermal Plates Performance Excellent dot reproduction, stable performance, big latitude Run length Unbaked: 100,000 impressions; Baked: 150,000 impressions Cost reduction High-speed plate, good ink-water balance, quick inking, high usage rate of printing ink. Suitability Compatible with mainstream thermal platesetter and plate processor, super adaptability Cost-effective higher Technical Parameters of CTP Thermal Plates Spectral sensitivity 830nm Laser energy required 130~150mJ/cm2 Resolution 1%-99% @200lpi.Suitable for FM screen UV ink adaptability Plates need to be baked Baked plate of conditions 230°C-250°C, 5-8minutes (Special gum should be used with baked plate ) Safelight 2 hours under the fluorescent light and white light. 12 hours under the yellow light. Transport and storage Keep CTP Thermal plates flat in packaging, Temperature should be between 5 °C and 30 °C (10- 26°C best) and humidity below 55% (40 -70% best). Maxim stacking height 1.2m Shelf life 12 months Developing temperature 24°C-26°C Developing time 20s-30s Dynamically added 130ml/m2 …

Nydia

Nydia

Sales Manager

Sales Manager