Coil color aluminum 3003 VS 3004 for roofing

3003 and 3004 are two typical alloys for coil color aluminum of roofing. At the very beginning, only 3004 was adopted in aluminum roofing. 3004 aluminum for roofing is made by hot rolling and aging treatment. Its basic thickness is 1.0mm, tensile strength is 300Mpa, elongation is more than 10%, magnesium content is between 1.2-1.5, and manganese content is between …

Application of 3005 aluminum color coil

3005 aluminum color coil is a common member of the coated aluminum family. 3005 aluminum, mainly composed of aluminum and manganese, is known for its excellent anti-rust properties and medium hardness. Plain 3005 aluminium alloy finds its applications in wet conditions or industrial products requiring a certain degree of hardness, like air conditioners, fridges, vehicles, cookware, food containers, chemical containers, …

Regular alloys and applications of coated aluminium coil

It seems all alloys can be made into coated aluminium coil, but in practice, only some are produced in large quantities based on their wide applications. Generally coated aluminum coil finds its applications in six fields: building, wild construction, interior and exterior decoration, advertising, transport and electronics. These fall in hundreds of specific uses, but corresponding alloys are only a …

Five types of color coated aluminum sheet

The color coated aluminum sheet is also known as coated aluminium sheet. It can be divided into five types in accordance with different paint types. Polyester color coated aluminum sheet Polyester is an anti-UV UV coating. The polyester resin has a polymer containing an ester bond in the main chain as a monomer, and an alkyd resin is added. The …

Paint Types for Color Coated Aluminum

How many types of paints are there for color coated aluminum products? At present Haomei mainly adopts water-based paints, the solvent of which is hydrophilic: acrylic, polyester, polyurethane, epoxy and fluorocarbon. Acrylic has a high hardness but poor flexibility (based on T-bend tests), suitable as high hardness index coatings for non-machined parts like automobile parts. Currently we apply it to …

Roller Coating Process of PVDF Color Coated Aluminum Coil

The roll coating process is an effective method to coat color coated aluminum with organic protective coatings. As a continuous and highly automated process, it helps to produce pvdf color coated aluminum coil rolls of better consistency than those from post-coating methods. Typical coating line systems require aluminium substrates of good moulding property, satisfying scratch-proof ability, beautiful appearance, excellent weather …

3003 PVDF Color Coated Aluminum Coil for Beverage Cans

3003 pvdf color coated aluminum coil is a regular product for beverage cans. It has good corrosion resistance, workability, printing ability and light weight. 3003 aluminum coil contains a certain content of manganese that is known for excellent corrosion resistance. As the most widely applied anti-rust aluminum coil, 3003 is not suitable for heat treatment, thus cold processing is the …

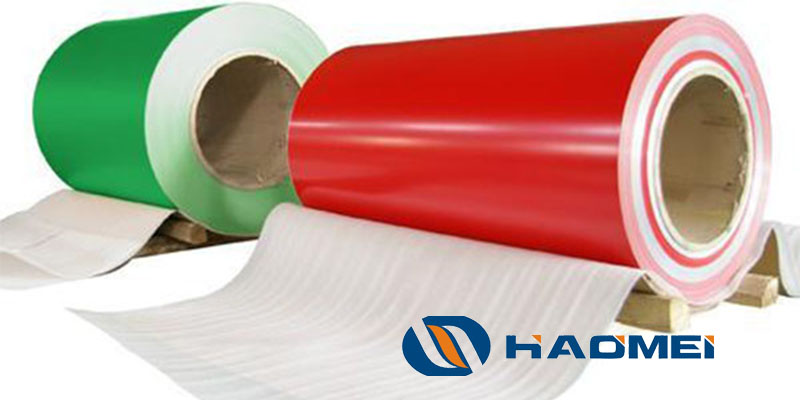

Color Coated Aluminum Strip Coils

Color coated aluminum strip coils refer to aluminum flat strap rolls with coated paints. Coated aluminum coil is also known as aluminum trim coil. Color coated aluminum strip is actually narrow aluminum trim coil. Regular alloys for it include 1050, 1060, 1070, 1100, 3003, 3004, 5052, 5005 and 5083 etc. The surface of the strip has been anodized before being …

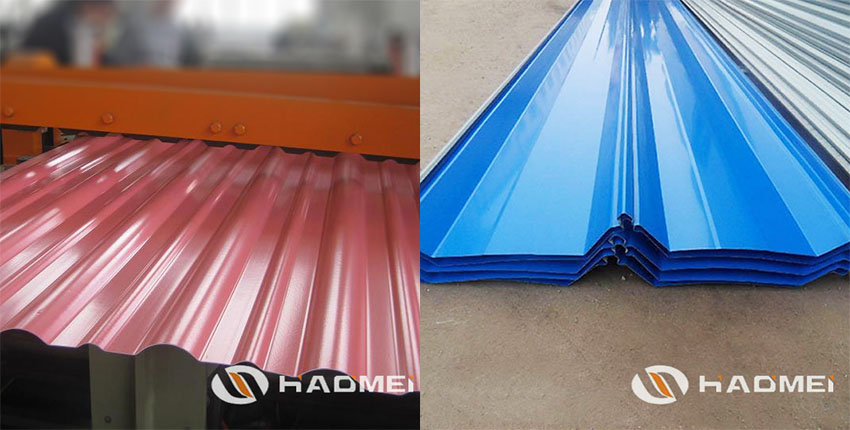

Surface Treatment of Color Coated Aluminum Roofing Sheet

Color coated aluminum roofing sheet can be divided into 10 series, among which 3xxx serves as the main material for building construction: roofing, ceiling, wall cladding etc. The alloys include 3003, 3003 and 3005. Generally there are two relative surface treatment methods for aluminum roofing sheet: plain treatment and paint coating. Plain treatment refers to the fact that no coating …

PVDF Color Coated Aluminum Coil Features

Briefly speaking, the color coating of aluminum coil refers to coating a layer of film onto the roll’s surface. PVDF color coated aluminum coils have stable properties, excellent corrosion resistance and long service life. Therefore, they bring about considerable profit in the long run. Color coated aluminum ranks top by light weight among regular industrial metals. It’s easy for workers …

Future Technical Development for Color Coated Aluminum Sheet in China

In the past years productivity of color coated aluminum sheets in China has kept rising owing to constantly growing investment in the industry. However, market regulation is always slower than the practical situation. The fact is that China color coated aluminum sheet industry is faced with over productivity, the reason for which include declining economic development, restricted export environment and …

Nydia

Nydia

Sales Manager

Sales Manager