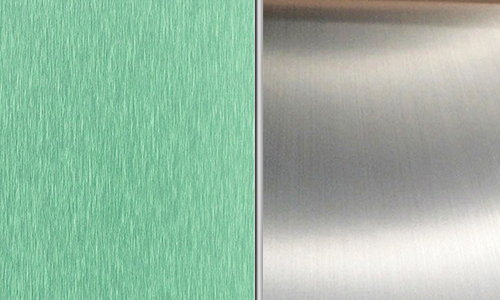

Brushed aluminium sheet VS mill finish aluminum sheet

Brushed aluminium sheets and mill finish sheets overlap in application fields like furniture, interior decoration and vehicles. But in those fields the former is usually more popular. What are the differences between the two, anyway? Surface Quality A mill finish aluminum plate gets an uneven surface easily from casual carrying or processing, while a brushed aluminum plate is much stronger …

New order of brushed aluminium sheet

Days ago we received a new order for brushed aluminium sheet for lamp parts. The alloy and temper is 1060 H14. 1060 is a regular grade of 1000 series, featured by good plasticity, low hardness, good anodizing effect and favorable price. The client was not confident in brushed aluminum sheet china, and he was inclined to purchase from American companies …

Surface treatment methods for brushed aluminum sheets

There are four surface treatment methods for brushed aluminum sheets: electrophoresis painting, powder electrostatic spraying, frosted fabric, multi-tone surface treatment and plasma enhanced electrochemical surface ceramization. 1. Electrophoresis painting: a surface treatment method adopted mostly in Japan. This brings out the smooth part of the aluminium sheet surface and enhances the corrosion resistance of the sheet. 2. Powder electrostatic spraying: …

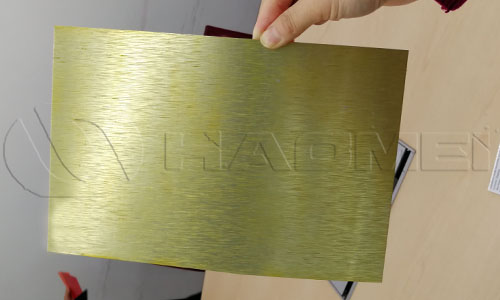

1060 brushed aluminium sheet for photo frames

Brushed 1060 aluminum sheet for photo frames is 0.1mm to 1.0mm thick, and up to 1600mm wide. The colors include silver, light gold, light blue, light copper etc. Since the quality of aluminum is much lighter than glass, anodized aluminum, especially the brushed anodized aluminum plate, has become the designated material for photo frame manufacturers. 1060 aluminium sheet has natural …

Brushed aluminium sheet for cell phone shells

The application of brushed aluminum sheets in cell phone shells is not novel any more. As long as years ago, Apple took the first step to adopt brushed aluminium to case its batteries, attracting public attention to the once unknown brushed aluminium. The bold creativity of Apple designers is based on excellent performances of brushed aluminium composite sheet: light weight, …

Brushed aluminium sheet for labels

Brushed aluminum sheets 4×8 are a type of aluminium product for labels with a given size. Other sizes are available, too, and the thickness of the sheets ranges from 0.18mm to 3mm. Further cut into small pieces of given sizes, they finally turn into delicate labels with logo designs or instructions for bags, dresses, art craft, ornaments, electronic items, machinery …

Brushed aluminium sheet for furniture and home appliance

A brushed aluminium sheet is a special friction extrusion plate falling on different patterns and specifications matching varied application conditions. While being used in furniture and home appliance, the sheet should be selected carefully. Purchasers should pay attention not only to the quality of the sheets, but also to the color, line pattern and anodizing film thickness. If you need …

Anodizing process for brushed aluminium sheet

Anodizing is an additional process for a brushed aluminium sheet. In other words, not all brushed sheets are anodized unless required by clients. Wire drawing and anodizing are two different aluminum plate surface treatment processes. Wire drawing is a manufacturing process in which an aluminum plate is forced to pass through the mold under the action of external force, during …

Brushed Aluminum Sheet Metal

Brushed aluminum sheets are obtained by a manufacturing process of repeatedly scraping aluminum plate out of the line with sandpaper. The technological process of brushed aluminum sheet china is mainly divided into three parts: degreasing, sanding machine and washing. All kinds of clipsal brushed aluminium cover plates colors are: jk001 ancient copper, jk002 green, jk003 stainless steel, jk004 blue, jk005 …

Nydia

Nydia

Sales Manager

Sales Manager