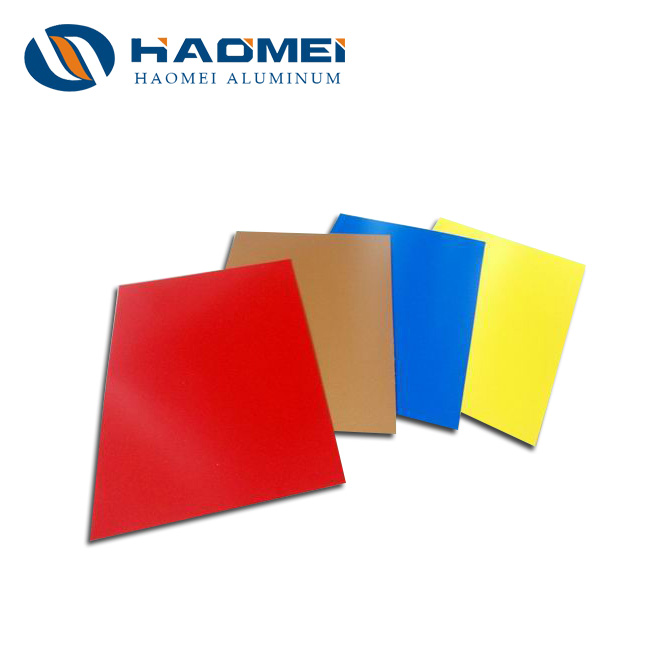

Red anodized aluminum sheet

The red anodized aluminum sheet has a thin layer of aluminum oxide on the surface, and the thickness thereof is 5 to 20 μm, and the hard anodized film is 60 to 200 μm. The anodized aluminum plate has excellent wear resistance (up to 2320K) , good heat resistance, excellent insulation, and high breakdown voltage (2000V). The oxide film has …

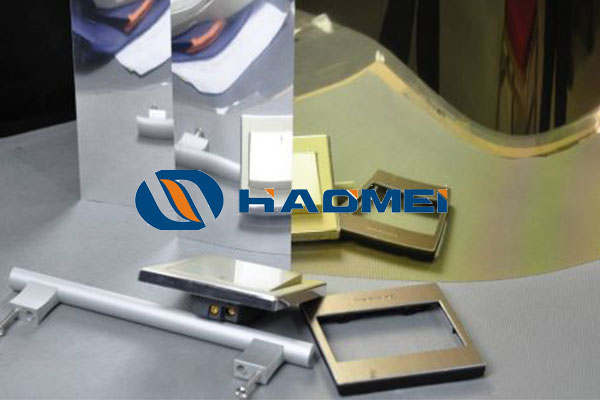

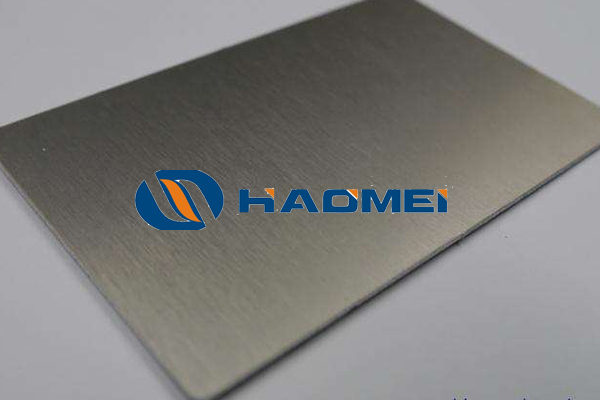

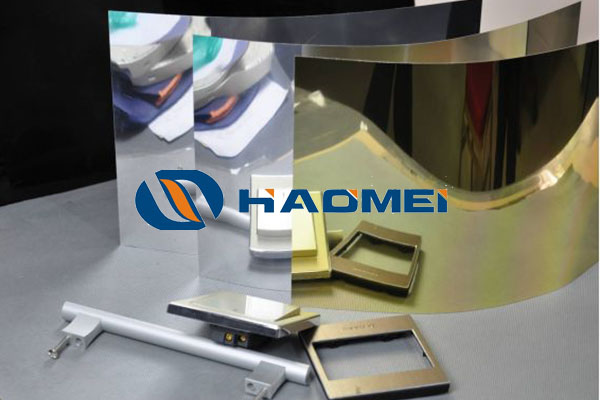

Polishing methods for clear mirror aluminum sheet

There are three polishing methods for clear mirror aluminum sheet: mechanical polishing, electrolytic polishing and chemical polishing. Mechanical polishing is generally the operation of pressing an aluminium sheet onto a rotating cloth wheel or other elastic wheel pre-coated with a polishing paste. The essence is to use the polishing wheel to smooth the extremely small unevenness on the surface. The …

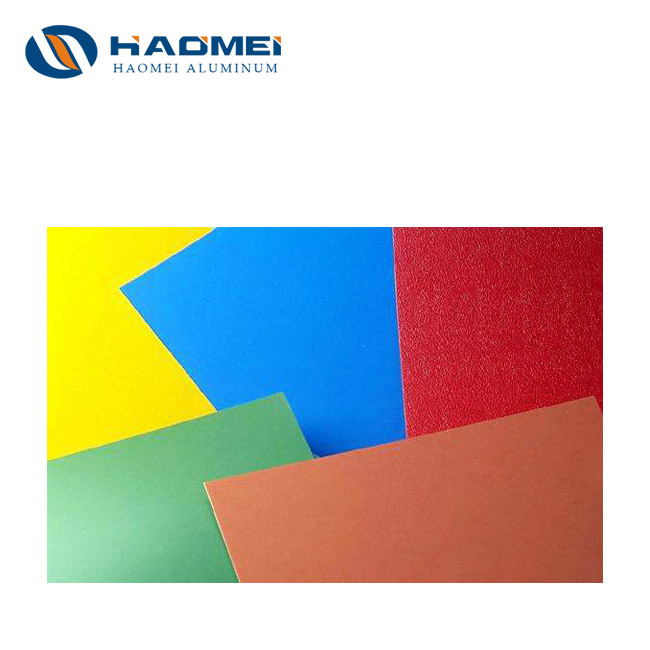

Blue anodized aluminum sheet supplier and manufacturer

The blue anodized aluminum sheet is a very common material with many advantages. Alloy aluminum sheet has good forming performance, corrosion resistance, weld-ability and medium strength, used to make airplane oil tank, oil pipe, as well as the transportation vehicles, ships’ metal parts, instrument, lamps stent and rivet, metal products, electrical enclosure, etc. Product Description of blue anodized aluminum sheet …

Buy aluminum sheet mirror polish here

The “aluminum sheet mirror polish” is a phrase created by clients’ searching way, the product is called mirror polish aluminum sheet actually. A aluminum plate can be mirrored after being polished and polished. The mirrored aluminum plate has a strong anti-corrosion effect, because aluminum is oxidizing and can form a dense aluminum oxide film on the surface, which can protect …

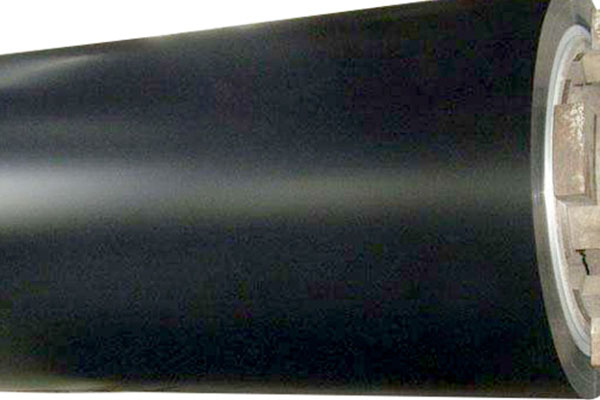

Anodizing process of black anodized aluminum sheet metal

The black anodized aluminum sheet metal is among the most popular type of andozied aluminium sheets. Aluminum itself is a kind of material with strong corrosion resistance. However, it will form aluminum oxide on the surface of aluminum after encountering oxygen in the air. After a long time, its anti-corrosion and stagnation resistance will be slowly relieved in this way. …

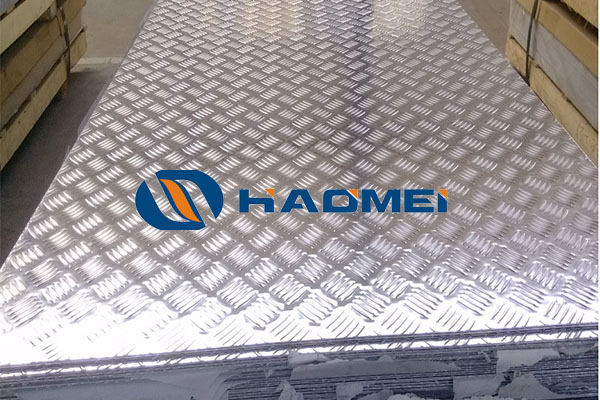

Aluminum checker plate sheet thickness measurement method

The method of aluminum checker plate thickness measurement is as follows. 1. Use a micrometer to directly measure base plate part of the target checker plate aluminum sheet. (Specification thickness is the thickness of the plate without pattern) 2. Measure several times different parts of the checker plate. 3. Work out the average of numbers obtained, which is the thickness …

Mirror finish anodized aluminum sheet color and features

The mirror finish anodized aluminum sheet is obtained by placing an aluminum mirror sheet in a corresponding electrolyte as an anode, and performing electrolysis under specific conditions and an applied current. The aluminum sheet of the anode is oxidized and a thin layer of alumina is formed on the surface. A mirror finish anodized aluminum sheet is featured by strong …

White anodized aluminum sheet advantages

White anodized aluminum sheet plates can be seen in the fields of cans, buildings, home improvement, electronics and so on. Some are simply anodized sheets, while others have gone through extra surface treatment processes like mirror finish. The white anodized aluminium sheet is also popular among the public because of its unique properties and its application range is extremely wide. …

Pot defect of gold anodized aluminum sheet

The gold anodized aluminum sheet is obtained by anodizing and electrolytic coloring of gold. With such a mature technology, an anodized aluminum sheet can be painted not only gold, but also black, brown, champagne, titanium and so on. However, immature processes in the industry lead to various defects on the sheet’s surface. Reasons for this include corrosion of acid and …

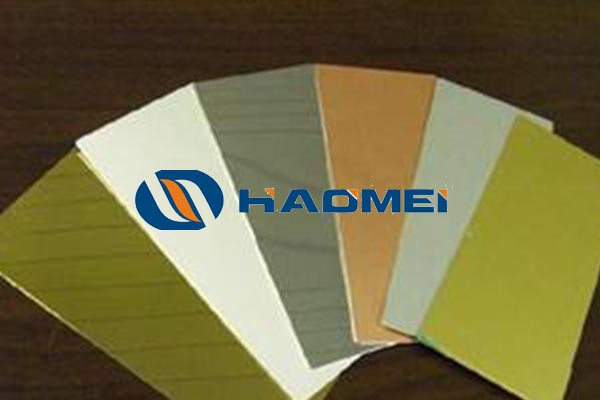

Features of anodized aluminum sheets for sale

Anodized aluminum sheets for sale are widely used in machinery parts, aircraft parts, precision instruments, architectural decoration, machine casings, lighting, consumer electronics, handicrafts, household appliances, interior decoration, signage, furniture, automotive decoration and other industries. They have features as below. (1) Good processability: The anodized sheet is highly decorative and moderate in hardness. It can be easily bent and formed for …

Black anodized aluminum sheet process and test methods

The black anodized aluminum sheet refers to an aluminium sheet that has gone through anodizing process and obtained a black film on the surface. Anodizing refers to a material protection technique in which a metal material forms an oxide film on the surface thereof by applying an anode current in an electrolyte solution. If not specifically indicated, the solution applied …

Aluminum mirror reflect sheet for reflective panels

One the the usages of the aluminum mirror reflect sheet is as a raw material for reflective panels of solar heat collecting systems. What are its advantages, then? The basic requirement of reflective panels are high reflectivity, which paves way to efficient heat collecting from the sunshine. As its name hints, the aluminum mirror reflect sheet is a kind of …

Nydia

Nydia

Sales Manager

Sales Manager