Bronze anodized aluminum sheet used in building

Bronze anodized aluminum sheet has a hard adhesive film with outstanding hardness and wear resistance. With a solemn color similar to traditional wooden furniture, the sheet serves as a novel material in exterior and interior decoration of buildings. Anodizing technology overcomes the defects of traditional aluminum alloy surface treatment technology in terms of hardness and wear resistance, and also overcomes …

Surface treatment methods for aluminum stucco sheets

Surface treatment methods for an aluminum stucco sheet include mill finish, anodizing and color coating. Each has its own functions and applications. Mill finish stucco embossed aluminium sheets have no extra treatment for the surface. This method is applied to stucco sheets for general uses, like fridge inner wall cladding, air conditioners, heat sinks, pipe insulation etc. The thickness ranges …

1050 silver lighting aluminum mirror sheet for sale

1050 silver aluminum mirror sheet is among our popular products for lighting. It can made into rolls or cut into pieces of given sizes, featured by high reflectivity (86% and above), strong temperature withstanding ability and long service life. Thickness of the mirror sheet ranges from 0.3mm to 0.48mm, adhesive force 5B, and pencil hardness 1H. It has passed tests …

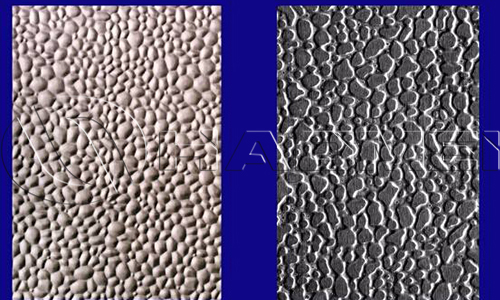

Can 5082 be made into pebbled aluminum sheet

A pebbled aluminum sheet is made by rolling the surface of a mill finish aluminium sheet with pebble patterns. It can be applied in packaging, wall cladding, tread panels etc. Ordinary alloys for pebbled aluminium sheets include 1100, 1060, 3003, 5052, 5754, 6061, 6063 and 6082, which exclude 5082. 5082 aluminum plate, just like 5052 and 5754, is an anti-corrosion …

6063 pebbled aluminum sheet application

6063 pebbled aluminum sheet is a representative extrusion alloy in the 6 series. It is a low-alloyed Al-Mg-Si series high-plasticity alloy. Its strength is lower than 6061. It can be used as a shape with complex cross-sections, corrosion resistance and surface treatment. After heat treatment, 6063 sheet is very suitable for the stretching process. Although the strength cannot be compared …

Surface treatment methods for brushed aluminum sheets

There are four surface treatment methods for brushed aluminum sheets: electrophoresis painting, powder electrostatic spraying, frosted fabric, multi-tone surface treatment and plasma enhanced electrochemical surface ceramization. 1. Electrophoresis painting: a surface treatment method adopted mostly in Japan. This brings out the smooth part of the aluminium sheet surface and enhances the corrosion resistance of the sheet. 2. Powder electrostatic spraying: …

Alloys and colors for brushed aluminum sheets

Variation of the processing methods of brushed aluminum sheets lead to color variation of the sheets. We can produce various colors of double-sided hair drawing aluminum plates: jk001 ancient copper, jk002 green, jk003 stainless steel, jk004 blue, jk005 red, jk006 silver, jk007 gold, jk008 copper, JK009 black, jk010 pink, jk011 brass, jk012 bronze, jk026 iron tree silver flower, jk036 Matt …

6082 aluminum sheet for sea shipping containers

6082 aluminum sheet is a regular material for shipping containers, with tempers of O, T4, T6 and T651. Haomei supplies specifications as below. Alloy 6082 aluminum sheet Regular tempers O, T4, T6, T651 Thickness(mm) 0.3-600 Width(mm) 500-2600 Length(mm) 500-16000 End products / Application sea containers Lead time 7-35 working days 6082 aluminum alloy belongs to 6××× series (Al-Mg-Si) alloy aluminum …

Can 3003 aluminum sheet be anodized

Can 3003 aluminum sheet be anodized? It’s said that 3003 aluminium is seldom anodized, for the sheet color is not even after being anodized. If you probe further, however, people are anodizing 3003 alloy sheets as a matter of fact. 3003 has manganese as its alloy metal, displaying excellent forming ability, high corrosion resistance, good welding property and outstanding electricity …

Induction disc/disk in aluminum sheet for sale

We have 1xxx and 3xxx induction disc/disk in aluminum sheet for sale. The disc is used in pizza pans, cookers, kettles etc. Specifications are as below: Alloy/grade: 1050 1070 1100 1200 3003 Thickness range: 0.2mm ~ 6mm Width range: 50mm ~ 1200mm Temper: O, H12, H22, H14, H24, H16, H26, etc. Rolling: Hot rolled and cold rolled both available Surface: …

Reasons for pot defect of polished aluminum sheet metal

The polished aluminum sheet metal is among the most popular aluminium mirror sheets for its excellent performance and luxurious color. In a previous article we discussed several reasons for pot defect of the sheet. Here we will proceed to deal with the other two reasons: damp wrapping paper board and inappropriate cleaning process. Paper or cardboard is used to separate …

Reasons for uneven film thickness of aluminium anodizing sheet plate

The uneven thickness of the anodized film of aluminum alloy, occurring frequently in production,seriously affects the subsequent electrolytic coloring and sealing effect of an aluminium anodizing sheet plate. The causes for this includes inappropriate solution temperature, effective area, contact state and sulfuric acid concentration etc. The temperature of the anodic oxidation liquid has an important influence on the uniformity of …

Nydia

Nydia

Sales Manager

Sales Manager