Mirror Finish Anodized Aluminum Sheet Maintenance 1

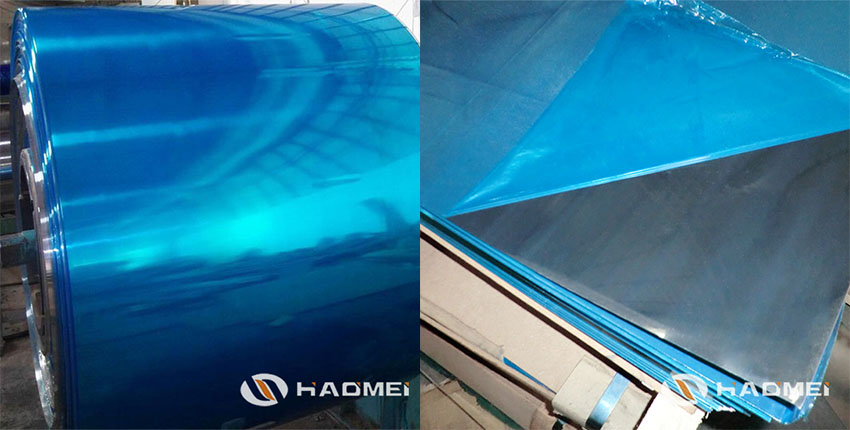

Semi-processed aluminium products plays an important role in our life. Take mirror finish anodized aluminum sheet for example. It serves as raw material at hour homes for items from furniture to wall panels. Then how to maintain the sheet effectively? 1. Do not tear off the protective film of a mirror finish anodized aluminum sheet product during installation, because accidental …

Features of Mirror Finish Anodized Aluminum Sheet for COB

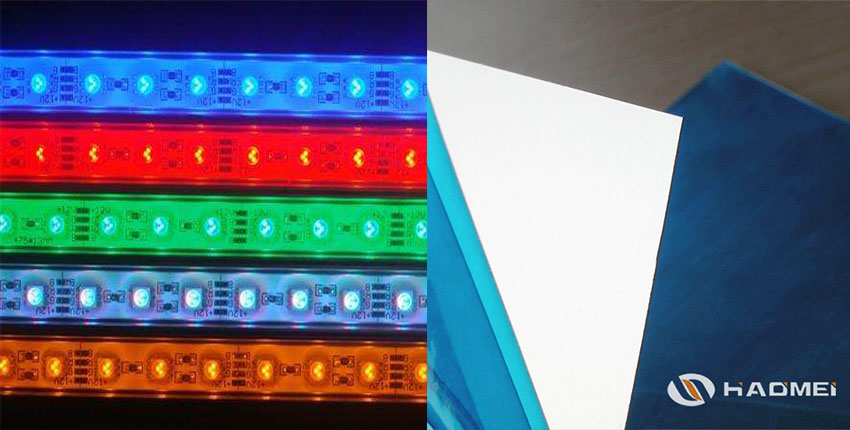

An aluminum substrate serves as one of the most important component for LED lamps. The most suitable aluminum product for the substrate proves to be mirror finish anodized aluminum sheet, which is featured by good heat exchange, high reflectivity, convenient operation and low cost. The technology of electrically neutral thermal path is applied to the substrate of mirror anodized aluminum …

Color Coated Mirror Finish Aluminum Sheet 1060 1100

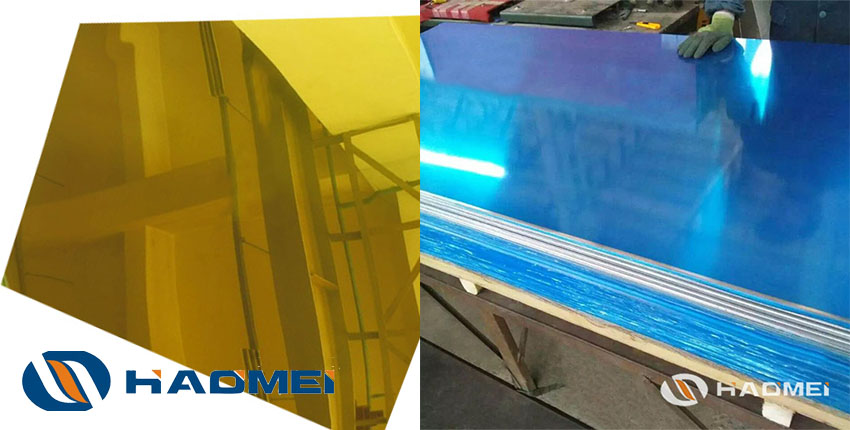

Color coated mirror finish aluminum sheet is more and more searched by people through kinds of searching engines. The phrase “color coated mirror finish aluminum sheet 1060 1100” has even become a heated word group on Alibaba. Speaking of application of the aluminum mirror sheet, we usually think reflectors and lamps, the function of which is closed related with natural …

Mirror Polished Aluminum Sheet Used for Lighting

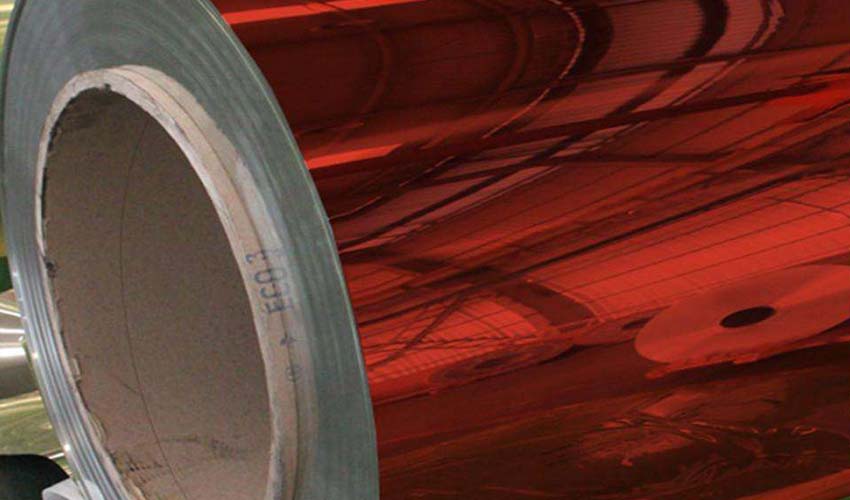

Mirror polished aluminum sheet is the most widely applied type of aluminum mirror sheet. The lighting industry serves as a big consuming market. Generally speaking, aluminium mirror sheet can be divided into two types in accordance with surface treatment methods: Polished Aluminum Mirror Sheet and Mirror Finish Anodized Aluminum Sheet. Polished sheets have poorer performances in reflectivity and stability. Usually …

Polished Aluminum Mirror Sheet and Mirror Finish Anodized Aluminum Sheet

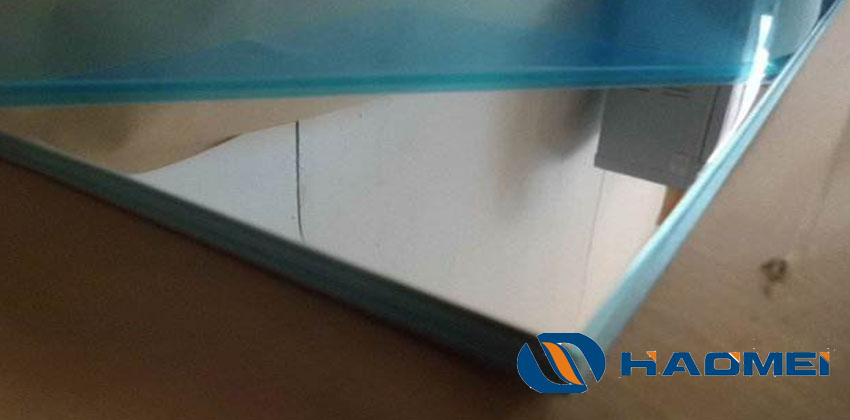

Polished aluminum mirror sheet refers to mirror alu sheet which has gone through a polishing process. Polishing means to make a piece of aluminium sheet become clean and bright through mechanical friction of its surface. This process is of little help in improving the sheet’s corrosion resistance which can be realized by anodizing, a kind of electric-chemical reaction during which …

Why is the Mirror Polished Aluminum Sheet So Widely Applied

The application of mirror polished aluminum sheet has extended to such a wide scope that we are usually surprised upon spotting them in some products. Sometimes it serves as a packing material for cosmetics and high end gifts, and on other occasions it becomes shells for expensive cell phones and laptops. You sees it as lamp covers on the street, …

Mirror Finish Aluminum Sheet Metal Used for Cupboards

Mirror finish aluminum sheet metal refers to anodized aluminum plates taking on an affect of mirrors. Superior aluminum mirror sheets have a reflectivity as high as 95%, and sheets of even higher reflectivity are said to have been produced successfully in an American laboratory. The newly developed sheet is expected to take place of glass mirrors in the future. Owing …

Mirror Finish Aluminum Sheet Metal Used as Cell Phone Shell

Mirror finish aluminum sheet metal can be applied in many industries, among which the most familiar to us is cell phone shell. Aluminum mirror sheet usually has alloys of 1050, 1060, 1070, 1100, 3003, 5005 and 5057 as its raw materials. As a relatively high end product, cell phone shells are generally made of 3xxx and 5xxx aluminium base sheets …

How to Color Reflective Aluminum Mirror Sheet

A reflective aluminum mirror sheet is mainly made of 1xxx, 3xxx and 5xxx series of aluminium. Most mirror sheets are of natural silver color, but some are colored to meet special application needs like decorative lamp parts and hotel ceilings. In contacting with buyers from various industries, aluminium manufacturers have developed colored sheet to cater for market demands. There are …

Mirror Finish Aluminum Sheet Metal Used for Labels

Mirror finish aluminum sheet metal refers to aluminium sheets with at least 80% reflectivity. Superior sheets can reach a reflectivity of 95% and above. Base plate alloys include 1050, 1060, 1070, 1100, 3003, 5005 and 5057. The sheet is used for labels because of its excellent decorative effect, good weather resistance and low cost. Mirror finish aluminum sheet metal has extraordinary …

How to Protect Mirror Finish Anodized Aluminium Sheet Surface

The protection of mirror finish anodized aluminium sheet surface consists of two parts: protection against chemical reactions and physical damages. Chemical reactions are likely to happen between oxygen in the air and active metals like aluminum. In manufacturing process of mirror finish anodized aluminium mirror sheets, a proper amount of other metals such as manganese, magnesium, copper and Zinc are …

Electrolytic Polishing Technique for Aluminium Mirror Sheet

Electrolytic polishing technique ranks among the most frequently applied surface treatment methods for mirror finish anodized aluminium sheets. It endows reflector aluminium mirror sheets with high brightness and reflectivity, making them suitable for various applications in decoration and reflection. In aluminum industry, electrolytic polishing refers to a technical method applying the principle of electrochemical anode dissolution to finish the surface …

Nydia

Nydia

Sales Manager

Sales Manager