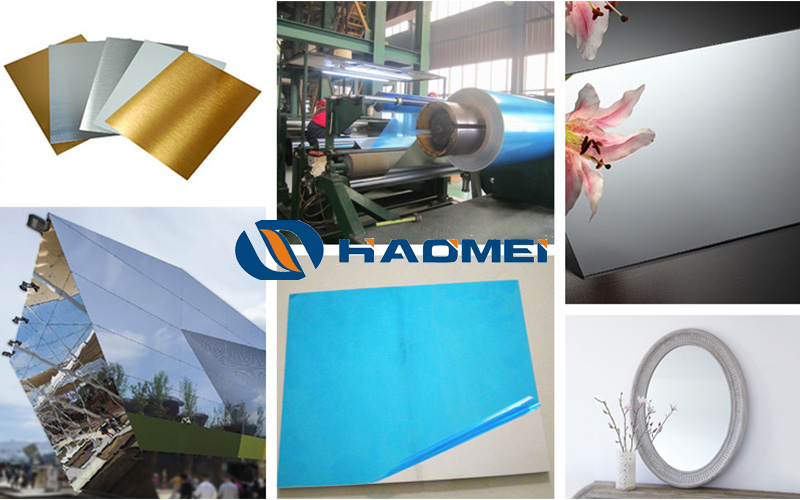

Mirror finish anodized aluminum sheet color and features

The mirror finish anodized aluminum sheet is obtained by placing an aluminum mirror sheet in a corresponding electrolyte as an anode, and performing electrolysis under specific conditions and an applied current. The aluminum sheet of the anode is oxidized and a thin layer of alumina is formed on the surface. A mirror finish anodized aluminum sheet is featured by strong …

Aluminum mirror reflect sheet for reflective panels

One the the usages of the aluminum mirror reflect sheet is as a raw material for reflective panels of solar heat collecting systems. What are its advantages, then? The basic requirement of reflective panels are high reflectivity, which paves way to efficient heat collecting from the sunshine. As its name hints, the aluminum mirror reflect sheet is a kind of …

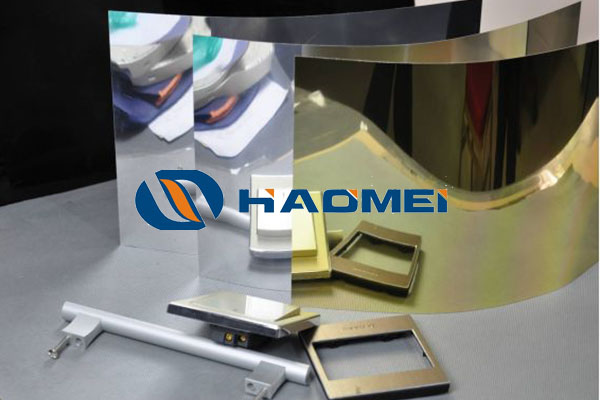

Aluminum sheet gold mirror

The aluminum sheet gold mirror is an anodized aluminum sheet which obtains a gold color on the surface that has gone through special processes. An aluminum sheet gold mirror is bright and clear with a beautiful color of gold. The anodizing film acts as a protective layer for the sheet itself, showing strong hardness, good wearing resistance and excellent corrosion …

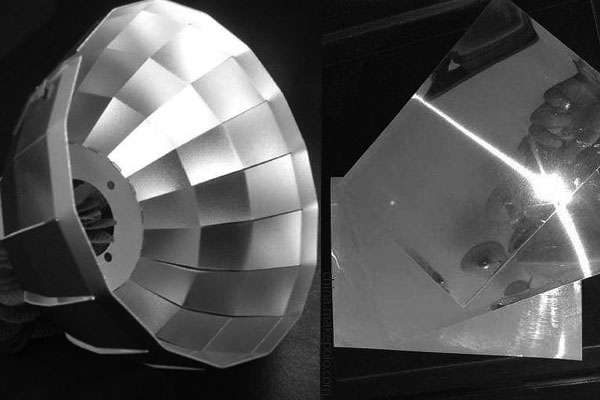

Aluminum mirror reflector sheet for lighting

Why is the aluminum mirror reflector sheet so widely applied? You will not wonder any more after learning about its pros. An aluminum mirror reflector sheet has a good heat dissipation. Going through the thermal electric separation technology, the sheet obtains a much higher thermal conductivity (137W), which greatly improves heat dissipation of the chip, while the thermal conductivity of …

Reflective Aluminum Lighting Sheet Used for Scutcheon

The reflective aluminum lighting sheet for scutcheon is an aluminum sheet developed especially as a raw material for scutcheon. Its oil adhesive force is good. Sheets that have gone through decrease treatment have clean surfaces so that there’s no need for cleaning before printing. Regular alloys for the sheet include 1050, 1060, 1070, 3003, 3005, 5005, 5052 and 5057 etc. Generally …

How to Guarantee the Effect of Oxide Film on Aluminum Mirror Sheets

The mirroring effect of an aluminum mirror sheet depends on quality treatment of both substrates and oxidation films. The surface of a substrate itself should reach a given reflectivity, and the matching oxide film should be highly pure and transparent. Here we would like to share how to guarantee the effect of oxidation film on a polished aluminum plate. At …

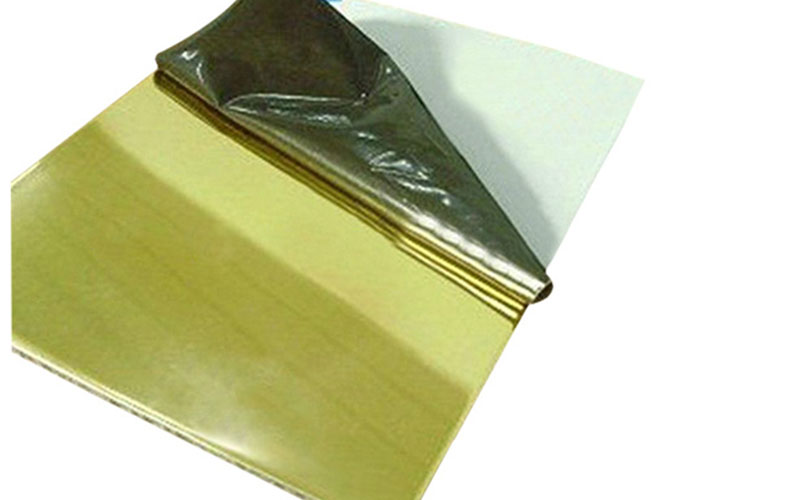

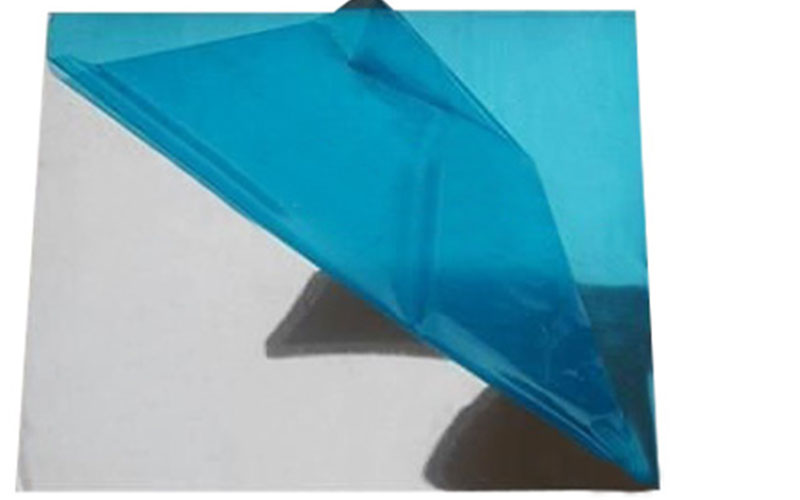

Difference Between Aluminum Mirror Sheet and Brushed Aluminum Sheet

There are many types of aluminum sheets which can be classified by usages, alloys and surface treatment methods. Aluminum mirror sheet and brushed aluminum sheet metal are two widely applied types. They are named because of different treatment methods, and they differ in application scope as well. An aluminum mirror sheet refers to aluminium sheets displaying a smooth bright surface …

Anodizing of Mirror Finish Anodized Aluminum Sheet

Anodizing is an important step for improvement of aluminum sheet’s corrosion resistance and colors. The production of mirror finish anodized aluminum sheet can not avoid such a process, either. An anodized aluminum sheet is applied in products of high requirements about surface and service life. Take the aluminum mirror sheet for example. It’s usually processed into furniture panels, ceilings, curtain …

Mirror Finish Anodized Aluminum Sheet for Curtain Walls

Main materials for curtain wall include stone, glass, plastic composite materials, aluminum panels etc. Raw material of aluminum panels can be further divided into plain aluminum sheet, color coated aluminum sheet and aluminum mirror sheet. The surface of mirror finish anodized aluminum sheet for curtain wall is very beautiful. The gloss is very high, and the color can be coated …

Mirror Finish Anodized Aluminum Sheet for Food Packing

Speaking of food packing, we would think of plastics, paper and aluminum foil, but few people would relate mirror finish anodized aluminum sheet to food packing. As a matter of fact, mirror anodized aluminum sheet takes up an even larger market in food packing. The reason why it rarely comes to our mind become it’s usually applied in packing of …

Mirror Finish Anodized Aluminum Sheet Maintenance 2

Aluminum mirror sheet refers to aluminium sheet taking on a mirroring effect. It has two types: polished aluminum mirror sheet and mirror finish anodized aluminum sheet. The latter is of better quality and performance. It covers a wide range of application in our daily life, such as exterior and interior decoration, home appliances, shells of digital products, kitchen utensils, tiny …

Mirror Finish Anodized Aluminum Sheet for Jewellery Cases

Jewellery cases have an ancient history in both China and other countries. There’s a well-known phrase in China telling that a man wants to sell a precious pearl. To emphasize rarity and valuableness of the pearl he prepared a beautiful case for it. Made of rare wood, the case is fragrant with little pearls, jades, agates and bird feathers. As …

Nydia

Nydia

Sales Manager

Sales Manager