Aluminium Slug for Tubes used in Toothpaste Packing

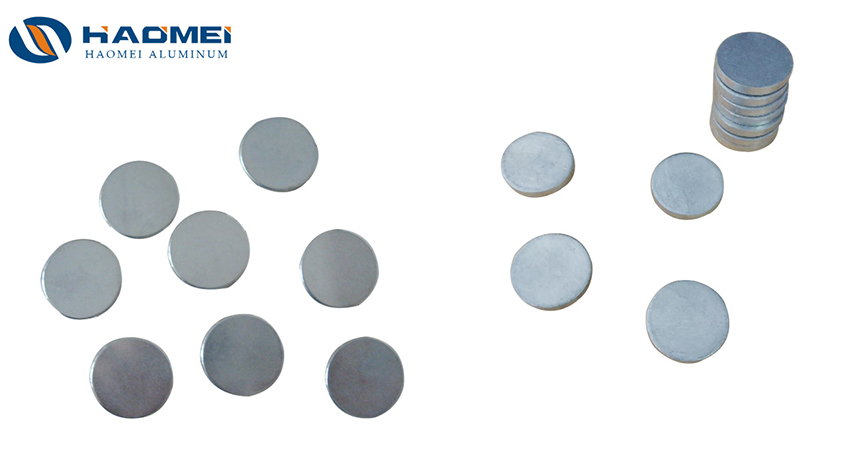

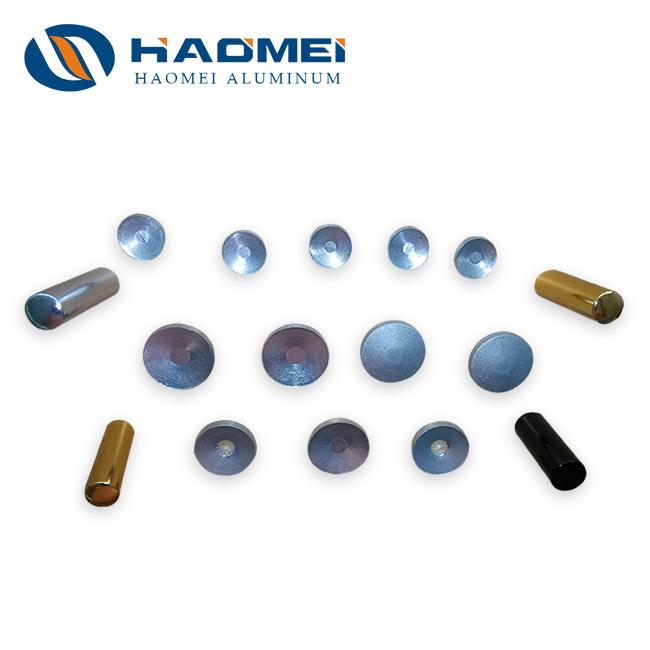

Aluminium slug for tubes is also called aluminum particles in China because of its mini size. One of its most popular applications is toothpaste packing. The slug is usually made of 1070 or 1060. Sizes for domed slugs include 13.15, 15.7, 17.7, 18.7, 21.7, 24.5, 24.7, 27.7, 29.7/29.8, 31.3, 31.4, 31.55, 34.65, 39.7, 44.7, 45.3, 49.65, 52.65, 53.3, 59.25, 65.7, …

Aluminium Slug for Tubes for Sale

The aluminium slug for tubes is also known as aluminum grain, aluminum pill and aluminum sand. It is refined by repeated drawing, cutting and grinding processes of aluminum ingots containing 99% aluminum. The perfect alloy for aluminum slugs proves to be 1070, the aluminum content of which is 99.7%. 1070 pure industrial aluminum has high plasticity, good corrosion resistance and …

Aluminium Slug for Tubes Manufacturers In China

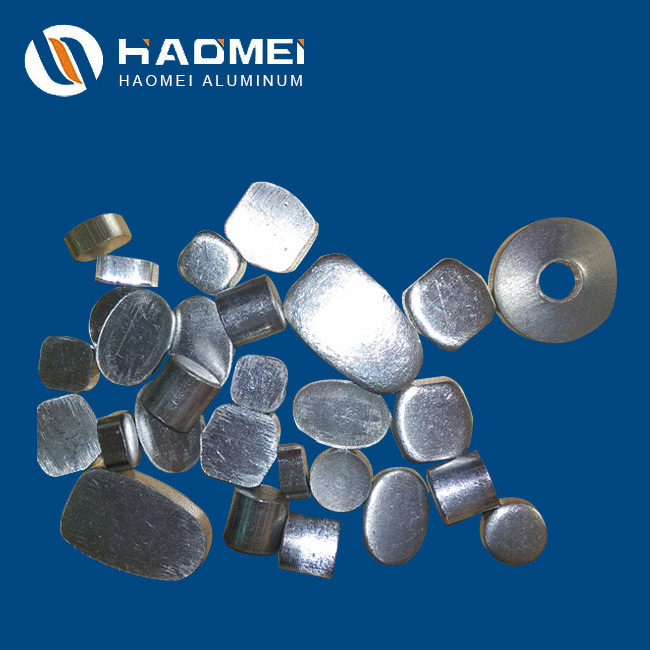

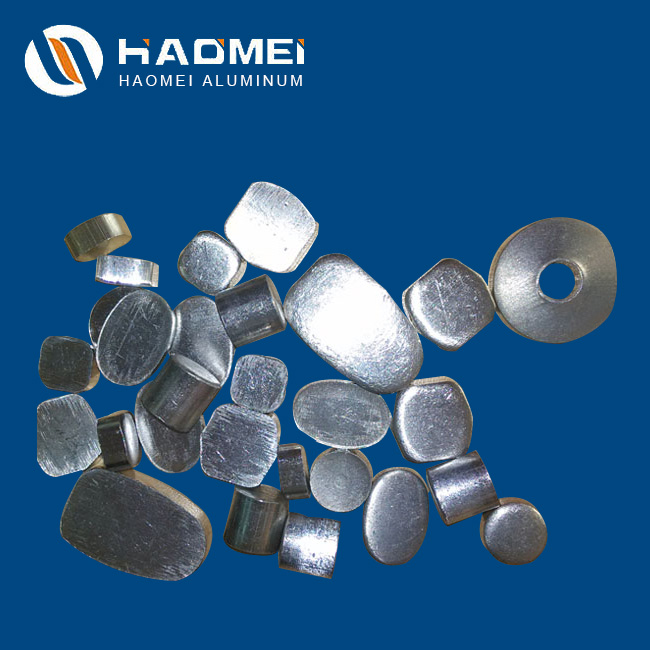

Established thirty years ago, Haomei is one of the most well-known aluminium slug for tubes manufacturers in China. It supplies 1050 and 1070 aluminium slugs of A class. Thickness of the slugs ranges from 2mm to 30mm and diameter from 10mm to 200mm. General shapes include flat round, dome, oval, rectangle, round with hole etc. Finished slugs have a tensile …

Aluminium Slug for Tubes Applied in Pharmaceutical Packaging

As elaborated in Application of Aluminium Slug for Tubes, aluminium slug for tubes can be processed into not only tubes but also cans, shells and housings for various usages. One of its most popular application proves to be pharmaceutical packaging. Aluminium slug for tubes is not the only aluminum-related product for pharmaceutical packaging. An even more ordinary product turns out …

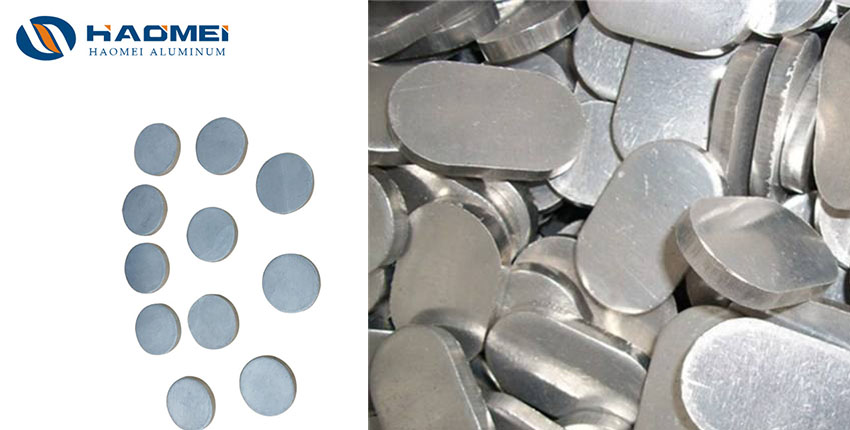

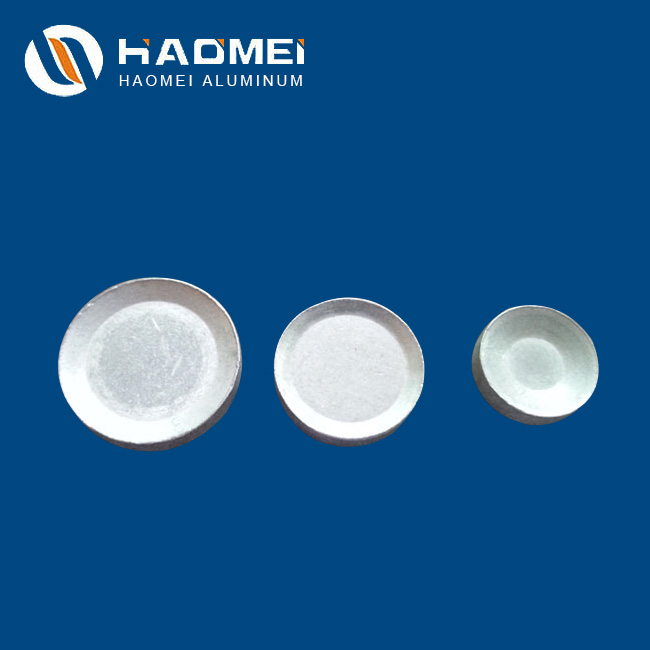

Aluminium Slug for Tubes

Aluminium slug for tubes is obtained by cold punching of thick aluminum strips. In other words, aluminum ingots are first processed into aluminum plates which are further cut into narrow strips for cold punching. Aluminum slug for tubes cover a wide range of shapes. There are round, rectangle, elliptic, dome and irregular shapes for special applications. Slugs of all these …

Manufacturing Process of Aluminium Slug for Tubes

Manufacturing process of aluminium slug for tubes consists of melting, hot&cold rolling, punching, annealing, surface treatment and packaging. At the beginning of melting, aluminum ingots are put into a melting pot which is heated to melt the ingots. Melted aluminum liquid is stirred continuously, and aluminum dross is removed from the liquid at the same time. When the liquid gets …

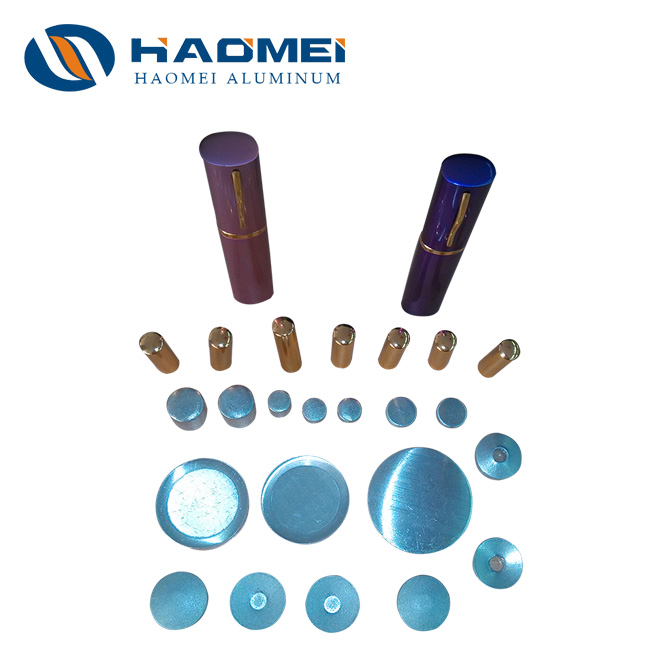

Aluminium Slug for Tubes Used for Phone Battery Covers

Aluminium slug for tubes covers a wide range of application, including tubes for cosmetics and medical liquid, beverage cans, capacitor covers and containers for other household articles. All the applications connect closely to our daily life. Take capacitor covers for example. The cover that we contact most frequently proves to be power battery cover of our cell phone. Aluminium slug …

Application of Aluminium Slug for Tubes

The title seems to be confusing because aluminium slug for tubes must be applied in tubes. However, it is not the case. Except tubes, it can be processed into bottles, covers and packaging materials of various shapes. Here we are going to elaborate on them one by one. Aluminium slug for tubes can be first made into tubes for diverse …

Why are Aluminium Slug for Tubes Used for Pop Cans

One of the most important application of aluminium slug for tubes falls on raw material of pop cans. Considering how many cans of beer and various other beverage people consume around the world everyday, the consumption of aluminium slug for tubes is really shocking. Although steel also takes a considerable share of raw materials for pop cans, aluminium slugs beat …

Aluminium Slug for Tubes VS Steel Slug for Tubes

Many people are confused about differences between aluminium slug for tubes and steel ones. In our daily life we can not avoid drinking beverage kept in pop cans. Some observant people notice material difference among the cans. Take porridge cans and beer cans for example. Not a few people in China like porridge with eight kinds of beans. When I …

Can Aluminium Slug for Tubes be Used for Cosmetic Containing

Speaking of application of aluminium slug for tubes, not a few suppliers would list cosmetic containing. However, many people have doubts about this. A guy called zhishen asked on Zhihu “Are cosmetics in aluminum tubes better?” This question attracted answers with different points of view. Some suggested that glass or plastic tubes would be better than aluminium ones. Others consisted …

Developing Prospects of Aluminium Slug for Tubes

Manufacturers of aluminium slug for tubes have been confronted with a tough challenge these years. Food industries, such as beverage and porridge etc, used to apply aluminium slug for tubes as raw material of cans. However, steel cans have been becoming more and more popular these years. Does it mean that aluminum slug have a negative prospect in these industries? …

Nydia

Nydia

Sales Manager

Sales Manager