Differences between 3003 and 1050 aluminium circle sheet pieces

3003 aluminium circle sheet and aluminium circle 1050 are two representatives of regular aluminium wafers. In fact, most of the aluminum products we have seen are made from aluminium circle sheet pieces after secondary processing. The quality of aluminium circle sheet is relatively light and not easily corroded, so it is widely used in transportation, such as aviation, automobiles and …

Aluminium circle 1050 price

The aluminium circle 1050 price is higher than 1050 aluminum sheet, for production of the former entails more processing steps. The aluminium circle 1050 is formed by adding a small amount of copper to pure aluminum, boasting excellent forming process characteristics, high corrosion resistance, good weldability and electrical conductivity, widely used in products with low strength requirements, such as chemical …

A new mould for metal aluminium circle manufacturers

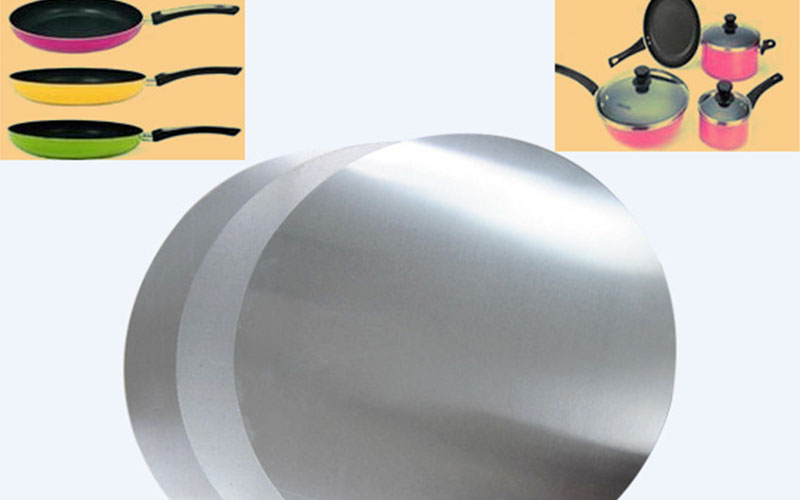

The aluminium metal circle is a raw material for capacitor shells, toothpaste tubes, shoe cream shells, medicine tubes and glue tubes etc. In particular, capacitor shells must be made of aluminium circle 1050 or other alloys with an aluminium content over 99%. In recent years China capacitor industry has developed so rapidly that it fully meets production requirements of both …

Classification of Aluminium Circle by Manufacturers in China

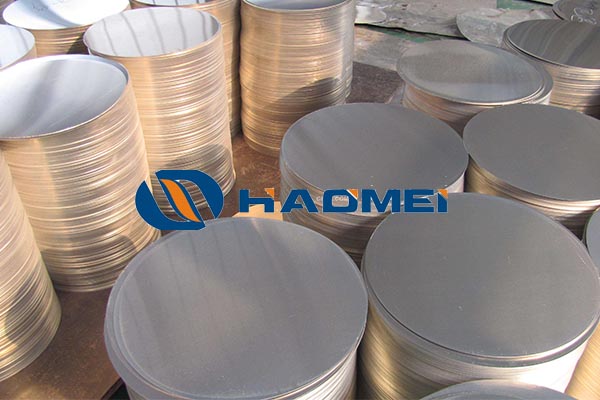

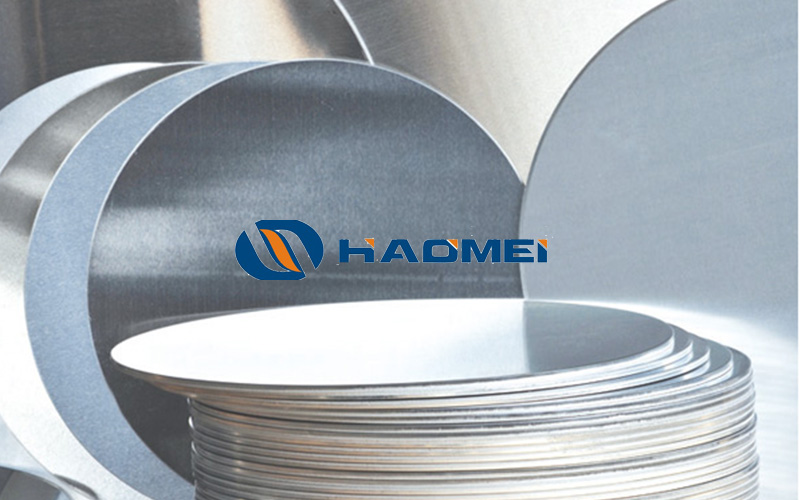

Aluminium circle manufacturers in China mainly classify aluminum circle discs by alloy, application and further processing methods. By alloys there are aluminium circle 1050, 1060, 1100, 1200, 3003 and 5052. 1050 and 3003 aluminium circle prove to be among the most frequently searched ones online. 3003 has harder strength and stronger corrosion resistance than 1050. Tempers for aluminium circles include …

1050 aluminium circle for cookware for sale

1050 ho temper aluminium circle is a regular product used for cookware and lamp parts. Its tempers include O, H12, H14, H16, H18, H22, H24, H26, H32 and H34. Aluminium circle 1050 are light in weight, excellent in tensile strength and good in corrosion resistance. Containing an aluminium content of 99.5%, it has a density only around one third of …

How to Improve Heat Treatment Process for Aluminium Circle 1050

Aluminium circle 1050 is widely used as a raw material for cookware, lighting and battery covers. In spite of its extensive application scope, the aluminum metal disk is confronted with various process problems. This article discusses about improvement methods of heat treatment process for aluminium circle 1050. The improvement of heat treatment process mainly contributes to decreasing the earring rate …

How to Test Aluminium Disc Earring Rate

As a crucial factor reflecting the quality of an aluminium disc, earring rate is attached to great importance to purchasers. Although it takes energy and time to make aluminum blanks into aluminium discs, high earring rate would wipe out all your effort in one day. Thus both manufacturers and purchasers do an earring rate test before large-scale production or buying. …

What influences earring rate of aluminum circle discs

Featured by excellent heat conductivity, easy forming and low price, aluminium alloys are widely applied in aerospace, transportation and communication industries. One of the most frequently used product is the blank aluminum discs for deep drawing or spinning. Most purchasers ask for samples before putting a formal order, because they need to test the sample pieces first. In addition to …

Aluminium Circle Production Features and Parameters

No superior aluminum wafers can be produced without excellent production lines. Many people search for aluminium circle manufacturers in delhi, yet if you want quality aluminum circle blanks, you need to keep your eyesight a litter wider. Rapid development of the logistics industry now enables you to obtain extraordinary aluminium circle 1050 and other alloys from abroad with relatively low …

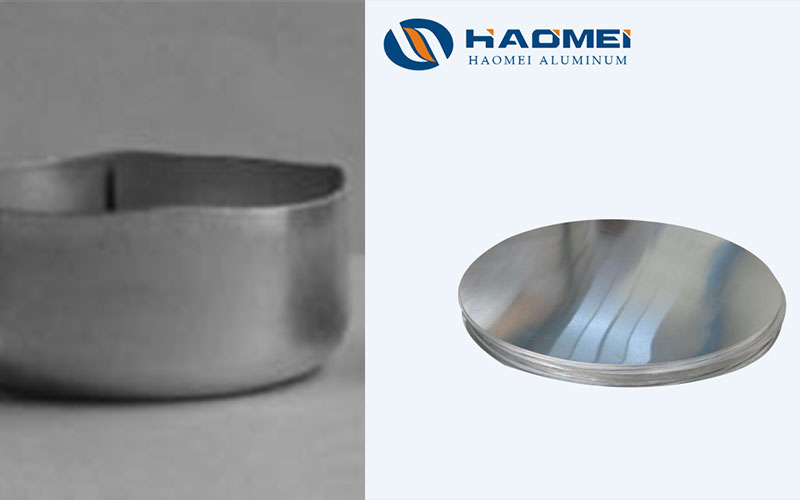

Aluminium Circle Advantages and Packing Methods

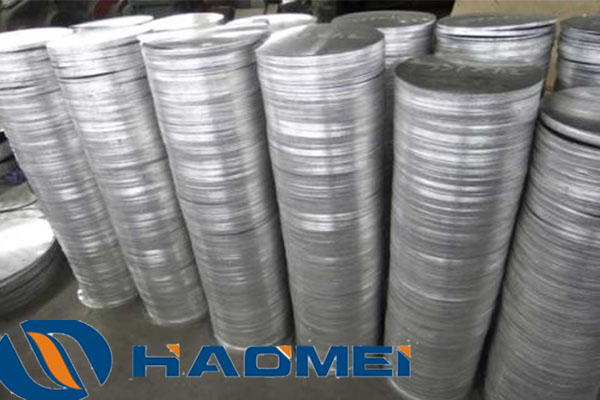

The production of aluminium circle are carried out on a fully automatic aluminum circle cutting machine from raw material feeding to casting and cutting. In other words, aluminium coil rolls are made into round aluminum plate pieces directly without almost any manual intervention. The advantage of this production process lies in avoidance of scratches on the surface and high precise …

Aluminium Circle 1050 Round Metal Discs for Sale

Our aluminium circle 1050 round metal discs for sale is manufactured by a fully automatic production line consisting of a feeding machine, a decoiler, a coil flattening machine, a conveying machine, a swaying aluminum circle cutter, a modular exchange device, a stacking unit, a waste material cutting unit and a control unit. This line entails no manual contacting with raw …

Features of Aluminum Circle Cutter for Aluminium Circle 1050

An aluminum circle cutter is also known as a pivoting feeder, a stamping and feeding equipment or a servo automatic yaw feeder. Here let’s take the model of NZRF-1300 for example. This machine can produce aluminium circle 1050, 1060, 1070, 1100 and 3003. It deals with aluminium sheets of thickness between 0.3mm and 3.0mm, and width below 1800mm. The largest …

Nydia

Nydia

Sales Manager

Sales Manager