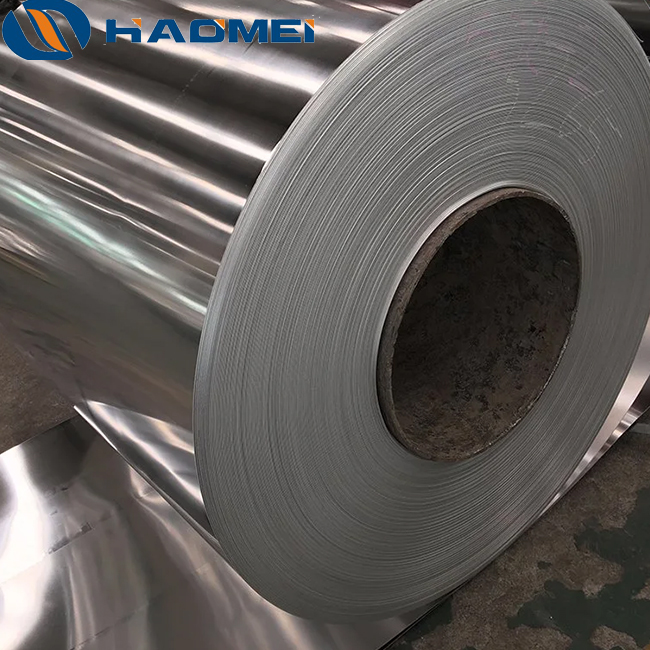

Aluminum coil 3104 alloy

A3104 aluminum coil, a deformed alloy with tempers including H111, O, H14, H16, H18 and H34 etc., has a maximum tensile strength of 275MPA and elongation up to 20%. As a deformed alloy, aluminum coil 3104 alloy has good forming ability, strong corrosion resistance and excellent welding ability. Further more, outstanding performances in tensile strength and elongation endows the coil …

3104 Aluminum Coil

Material: Aluminium Type: Coil, roll Certification: CCS,GL,DNV,ROHS, SGS, ISO Type 3104 Aluminum coil/roll Standard ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006 Material 1000 Series:1050,1060,1070,1080,1100,1235,1A25,etc. 2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. 3000 Series:3003,3004,3104,3105.3204,3A21,etc. 5000 Series:5005,5025,5052,5056,5083,5754,5A05,etc. 6000 Series:6060,6082,6083,6063,6061,etc. 7000 Series:7005,7050,7075,8011etc. Specifications Thickness 0.2-200mm or as your required Width 300-2600mm or as your required Length 100-100000mm or as your required Surface Bright, polished, hair line, brush, sand blast, checkered, embossed, etching Temper O-H112 Alloy 1050.1060.1100.1070.3003.3004.3105.5052.5754.5083.6061.6063.6062.7075.8011 Application of 3104 aluminum coil/roll 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. Trade Information Packaging Details Wooden pallet …

Nydia

Nydia

Sales Manager

Sales Manager