Top quality 3003 aluminum coil for letter

3003 aluminum coil for letter is a painted or anodized aluminium product with an alloy metal of manganese alloy. 3003 is the most widely used of all alloys. It is basically a commercial pure aluminium and is 20% stronger than 1100. It has good hardness, corrosion resistance but relatively poor anodizing property. Anodized 3003 aluminum sheets or rolls might have …

Is 3003 aluminum coil used for beverage cans

3003 aluminum coil ranks top in popularity among Al-Mn aluminium sheet rolls which serve as an excellent material for beverage cans. 3003 used to be used in beverage cans. Due to the manganese alloy element, it shows excellent anti-rust properties. Aluminum will form an oxide film on the outside in the air, namely aluminum oxide, which prevents aluminum from being …

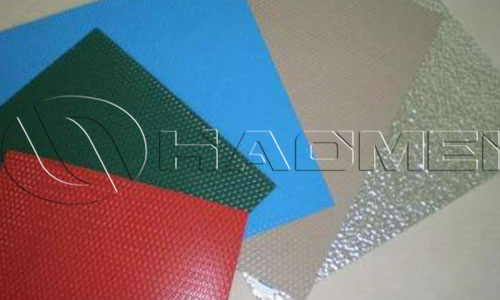

Advantages of 3003 aluminum painted emboss coil for roofing

3003 aluminum painted emboss coil for roofing is water-proof, heat insulating, uv resistant and light. 3003 aluminum coil serves as an excellent cookware material. Aluminium pots made of it are used to boil and contain water as a daily household item. Therefore, aluminium has a natural water-proof ability regardless of its alloys and grades. While being used as a roofing …

3003 pe aluminum coil for cell ceiling

3003 pe aluminum coil for cell ceiling is used as a particular ceiling material with light weight, sustainable color and long service life. 3003 aluminum coil ranks top in 3000 series of aluminium products either with a checkered service or a color coated surface. There are several reasons for the popularity of 3003 in various industries. It has a medium …

3003 aluminum roof coil specification and price

3003 aluminum roof coil is an Al-Mn series color coated aluminum coil for roof sheet. Its thickness ranges from 0.6mm to 1.2mm, and width can be as big as 1600mm supplied by Haomei. Detail specifications are: Temper: H14, H24, H26 Thickness: 0.6mm,0.7mm,0.8mm,0.9mm,1.0mm,1.2mm; Width: 55mm-16000mm Color: gray, bright silver, blue, red, green etc. Unlike 3004 that contains some magnesium, 3003 aluminum …

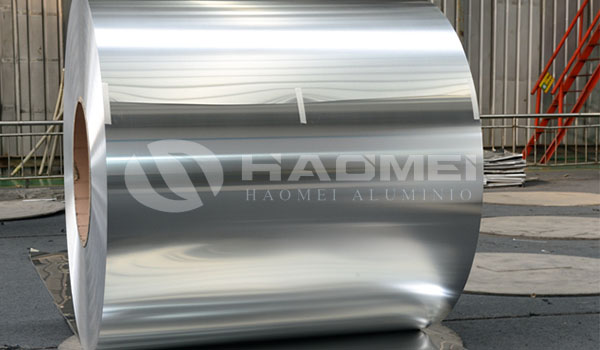

Aluminum coil for exporting

We have aluminum coil for exporting of 1xxx, 3xxx and 5xxx series, represented by 1060, 3003 and 5182. Aluminium trim coil is available, too. 1xxx series of aluminium coil products include 1050, 1060, 1070 and 1100. These are also known as pure industrial aluminium, for aluminium metal takes up an overwhelming share of them. 1060 aluminium coil contains 99.6% aluminum …

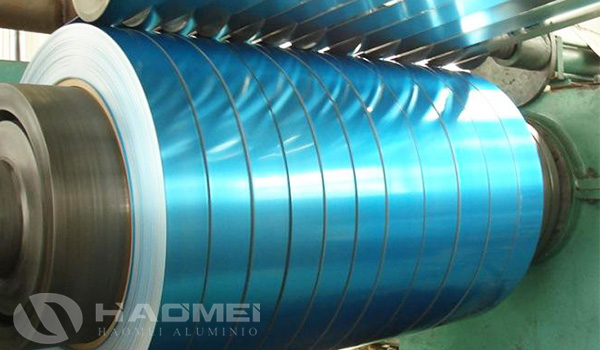

3003 shutter strip aluminum coil

3003 aluminum coil is a shutter strip coil of long service life. We have H19, H18, H26 and h28 strip of 0.2-3mm thick. As a member of Al-Mn series, 3003 coil has a low strength in comparison with 5xxx, 6xxx and 7xxx aluminium alloy grades. The participation of manganese strengthens erosion resistance of 3003 substantially, making it a well known …

3003 aluminium alloy aluminum coil manufacturers

3003 aluminium alloy aluminum is a widely used anti-rust aluminum. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. Its strength is not high(slightly higher than industrial pure aluminum) and it can’t be heat treated, so the cold working method is …

3003 h26 aluminum coil supplier

3003 h26 aluminum coil is a regular product of aluminum manganese alloy series, featured by good formability, solubility and corrosion resistance. It contains Silicon Si: 0.60, iron Fe: 0.70, copper Cu: 0.05-0.20, manganese Mn: 1.0-1.5, zinc Zn: 0.10, others: single 0.05 (total 0.15) and aluminum allowance. Due to the adding of manganese element, 3003 has excellent rust proof characteristics, also …

3003 aluminum coil for power battery

The 3003 aluminum coil is one the most commonly applied aluminum alloy of 3000 series. It contains a large content share of aluminum and little manganese which performs excellent anti-corrosion property. With stronger hardness than 1100 aluminum coil, it shows good workability, high corrosion resistance, satisfying welding property and extraordinary electricity conductivity. This type of aluminum coil can not be …

Properties and price of 3003 h14 aluminum coil

3003 H14 aluminum coil is an aluminum coil of 3003 grade and h14 state. H indicates the cold working hardening state, and the following numbers indicate the different degrees and types of cold working hardening. H1 represents the pure work hardening state. It is the last cold rolled product. Without additional heat treatment, the h1* aluminum coil has a relatively …

What are the Differences between 5052 and 3003 Aluminum Coil

As known to all, both 5052 and 3003 aluminum coil boast excellent corrosion resistance, and their applications are confusingly crossed. Sometimes it’s really difficult to distinguish one from the other while choosing suitable raw materials. Here we have a simple introduction to differences between the two alloys by comparing 3003H24 and 5052H24. First, they contain different chemical elements, because 3003 aluminum …

Nydia

Nydia

Sales Manager

Sales Manager