Surface treatment methods for aluminum strips

August 24, 2020

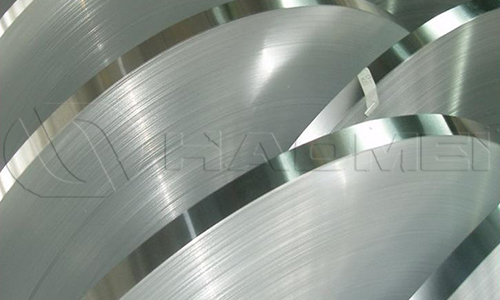

When we speak of aluminum strips, we usually refer to thin flat aluminum strips of less than 4.0mm thick rather than profiles of T or L shapes. This kind of aluminium strips are usually used in transformer winding, heat sinks, decoration, channel letters, bottle caps and so on. Corresponding to different application fields, surface treatment methods for them vary, too. Ordinary methods include brushing, anodizing and color coating.

Brushed aluminum strips are usually used for decoration and channel letters. The brushed lines are usually clear and regular, horizontal to the edge of the strips. The purpose of brushing an aluminium strip is to make its surface more beautiful and decorative. Although the surface is not smooth, it becomes rather even during the brushing process. In addition to channel letters, brushed strips are applied to furniture ornament stripes, clothing and bagging labels, office partition cladding etc.

Anodizing sometimes goes together with brushing in processing of aluminum strips, when the strips need to be strengthened in surface quality and coated at the same time. Anodized aluminum strips share similar properties with anodized aluminium sheets, and brushed anodized strips are beautiful in appearance, luxury in metal sense, high-end in product level and long in service life. They combines advantages of brushed and paint colored strips, yet covers a wider range of application. It’s not exaggerating to regard them as the best aluminium strips of all. In spite of this, some application areas, like transformer winding, do not adopt them, for the anodized film only functions to reduce conductivity, which is against the principle of aluminium strip for transformer.

Coated aluminium strips usually refer to strips coated with metal paints like PE and PVDF, although anodizing has the same function. Aluminum strips might be coated before being slit into stripes, and then treated with clad by the edge while being used as channel letter aluminium strips. In addition, aluminium strips can also be coated and printed with logos and designs as required by purchasers of bottle cap manufacturers who further process the strips into deep and shallow caps for wines, medicine, cosmetics etc. It’s worth mentioning that aluminium strips for bottle caps are totally different from so-called aluminium capping strip, a profile used for capping the adjoining sections of two pieces of flooring or ceiling panels.

In spite of diversity of surface treatment methods, flexible aluminum strips of different treatment methods fall on varied application fields. For example, mill finish strips are used in transformer and heat sinks, while coated and anodized ones in channel letters and decoration purposes. Therefore, experienced suppliers like Haomei are able to supply specifications and quotations immediately after receiving demands from a purchaser of a given area.

Nydia

Nydia

Sales Manager

Sales Manager