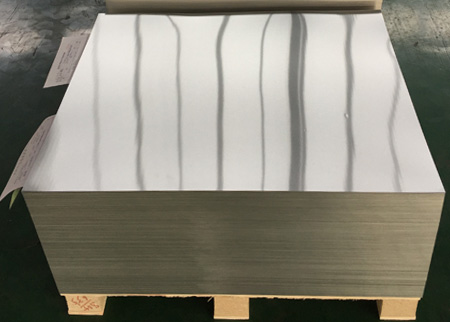

Small Aluminum Sheet

November 7, 2022

Small aluminum sheet are made by cut to size of aluminum roll, aluminum sheet manufacturer produce it with high accuracy and clean edge. The common size of aluminum sheet are 4X8, 5×10, 3×3 and so on. There are many cutting methods and machine for small aluminum sheet. If the shearing machine cuts it out, it is relatively flat and has no burrs, but the pattern is simple. The plasma cutting machine can cut it arbitrarily, but the cutting edge has burrs and is not flat. Laser cutting can combine the above advantages, but the price is relatively high.

Laser cutting small aluminum sheet also depends on the power of the laser generator. The thickness of 6000W can be cut to 16mm, and the thickness of 4500W can be cut to 12mm, but the processing cost is only high, because it is a highly reflective material, and laser cutting uses focused high-power density laser beam irradiates the workpiece, so that the irradiated material rapidly melts, vaporizes, ablates or reaches the ignition point, and at the same time, the molten material is blown away by the high-speed airflow coaxial with the beam, so as to realize the cutting of the workpiece.

The advantages and advantages of laser aluminum sheet cutting are as follows:

1, Cutting quality: excellent inclination angle, small area affected by heat, basically no slag, and can achieve good to excellent fine cutting results under the narrowest camber conditions

2, Small thermal deformation: The laser processing of laser processing has thin slits, high speed and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

3, Production capacity: extremely fast when cutting metal materials of various thicknesses, extremely fast perforation speed, and the cutting torch can be quickly disengaged, which improves production efficiency. When cutting small aluminum sheet metal materials with a thickness of less than 6mm, the speed is extremely fast, the thicker the metal , the slower the speed, the thicker the metal, the longer the perforation time.

4, Operating cost: The consumables have a long service life, good production efficiency, and excellent cutting quality, resulting in a lower cost per operation than other technologies.

Nydia

Nydia

Sales Manager

Sales Manager