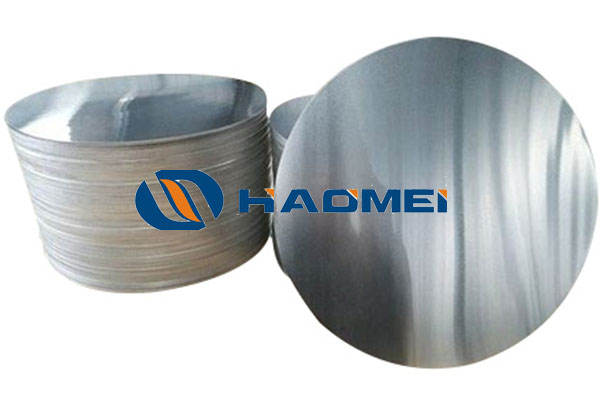

Round metal blanks

May 28, 2019

Round metal blanks take up an increasingly large market share. We used to discuss aluminum circle blanks only, which are only a member of round metal blanks. In addition to aluminum blanks, there are also steel blanks.

Steel circle blanks are also known as stainless steel circle blanks, whose corrosion resistance has a lot to do with its alloying contents and internal structure. The alloying metals include chromium, nickel, titanium, silicon, aluminum, manganese, etc, among which the stablest is chromium. It forms a passivation film on the surface of the steel to isolate the metal from the outside, protect the steel sheet from oxidation, and increase the corrosion resistance of the steel sheet. The damage of passivation film will lead to reduction of its corrosion resistance.

As regular round metal blanks, aluminum circle blanks and stainless steel circle blanks have similar application scopes, such as building materials, cookware parts, art instrument, decorative materials, reflective parts etc. Generally speaking, steel blanks have better strength and corrosion resistance than aluminium circle blanks, but they are replaced by the latter as long as the conditions are suitable, because aluminum circle discs have a lighter weight and a cheaper price.

Nydia

Nydia

Sales Manager

Sales Manager