Prospect of Lacquered Aluminum Coil Sheet for Ropp Caps

August 14, 2018

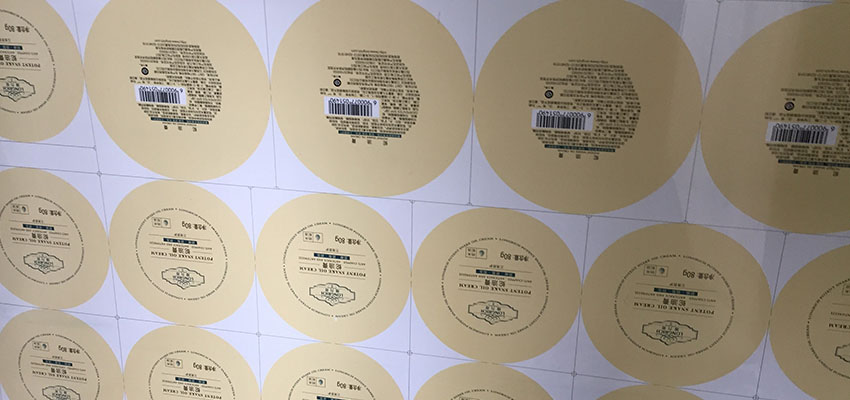

Lacquered aluminum coil sheet for ropp caps takes up a large share of market in industries like liquor, can food, cosmetic and pharmaceutical industries. It has a promising prospect in the market.

Lacquered aluminum coil sheet for ropp caps boasts better properties and lower cost than plastics. Aluminium ropp caps have excellent sealing performance, simple structure and good adaptability. Different from plastic caps, they have little size error in spite of big errors of glass bottles and therefore display better sealing effect. The aluminum sheet is so adaptable that it can be printed with more complex anti-fake designs by advanced techniques. Besides, lacquered aluminum coil sheet for ropp caps is much more environmental friendly. Plastics adsorbs dust in the air owing to static electricity during production of ropp caps, and it also produces scraps that cause serious pollution to bottled products. Some cap manufacturers even adopt inferior plastics. Further more, a part of the plastic cap is fixed around the bottle, which proves to be difficult to be recycled. Aluminum caps are free from all these problems. They have no pollution and can be recycled more easily. Benefiting from simpler manufacturing process and structure, they cost only half of plastic caps.

Cap manufacturers are more willing to adopt lacquered aluminum coil sheet for ropp caps because of its advantages mentioned above. Statistics show that a half of liquor produced in China each year is sealed by aluminum caps, and the figure is still keeping rising. Other industries like cosmetics and pharmaceutics are expanding rapidly as well. With enhancement of living standard in many countries, these industries will develop swiftly without doubt, because they are basic industries providing necessities. Correspondingly the application of lacquered aluminum coil sheet for ropp caps will expand greatly around the world. Therefore, manufacturers of the aluminium coil sheet has a promising future under the pre-condition that they supply good quality products.

Nydia

Nydia

Sales Manager

Sales Manager