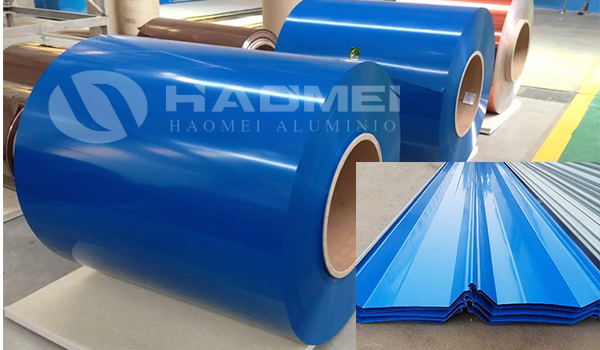

Prepainted aluminum roof coil

June 23, 2020

A prepainted aluminum roof coil is an coil roll of the aluminum-magnesium-manganese alloy, usually including A3004H24, A3004H26 and A3003H24. Haomei aluminium roof coil stocks are from aluminum giants and the paints from PPG. Our prepainted roofing coil goes through a fluorocarbon roller coating processing, widely used in roofing for airports, railway stations, offices, civil buildings etc.

Regular specifications are as below.

Grade: A3004H24, A3004H26, A3003H24;

Thickness: 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm;

Width: 55mm to 1600mm;

Color: Common silver gray, bright silver, champagne silver, steel, etc. thousands of colors.

Differences between 3003 and 3004 prepainted aluminum coil for roofing:

1. Mechanical properties: 3004 contains an extra alloy content of magnesium, which makes it softer and more corrosion resistant.

2. Price: 3004 is about $200 more expensive per metric ton.

3. Application: 3003 is harder and can not be bent hard.

4. Service life: similar, depends on quality of surface paints.

Two representative prepainted aluminum roof coil of Haomei:

1. Self-cleaning PVDF coated aluminium coil coated with super self-cleaning paints. The coating gives off chemicals removing stains and dust from wind, frost, snow and rain that attacks the roofing sheet surface. Although such a coil shares a similar appearance and size scope with common PVDF rolls, the application effect distinguishes them out of each other.

Heat-reflective PVDF color coated aluminum coil. The secret also lies in composition of the paint. Special ceramic components reflect UV and takes in visible lights at the same time. Such a coil is applied in a kind of cooling roof that needs little heat to be transmitted.

Nydia

Nydia

Sales Manager

Sales Manager