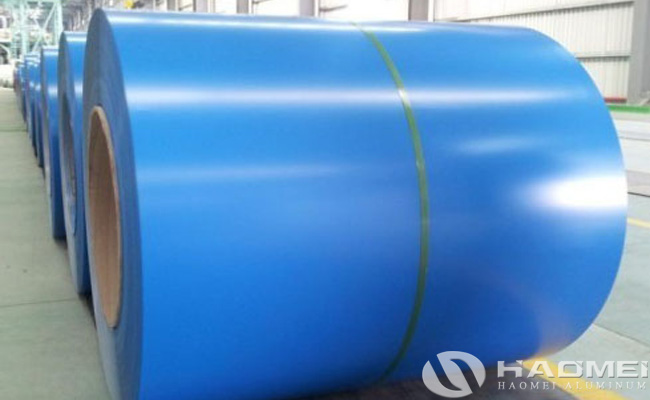

Prepainted Aluminum Roof Coil

August 22, 2022

Prepainted aluminum roof coil is widely used in the roofing of large public buildings, public workshops, prefab houses, and integrated houses. Its performance is very stable, it is not easy to be corroded, the surface layer can reach 30 years of quality after special treatment, and the weight per unit volume is the lightest among metal materials. Aluminum-magnesium-manganese alloys prepinted aluminum coil for roofing and exterior walls generally adopt the pre-roll coating (Coil Coated) process, which has the advantages of good color difference control, uniform paint film, high quality stability, and environmental protection. The type of coating generally uses PVDF fluorocarbon paint containing more than 70% of fluorocarbon resin.

The specification of prepainted aluminum roof coil are:

Material: AL1100, AL3003, AL3004, AL3105, AL5005, AL5052

Coating: Fluorocarbon coating, polyester coating, wood grain, printing, varnish Thickness: 0.25mm-4.00mm

Coating thickness: PVDF (fluorocarbon) >=25micron POLYESTER (polyester)>=18micron

Impact resistance: 50kg/cm, no paint peeling and no cracks, polyester color is used for 20 years, fluorocarbon is used for 30 years without decolorization and paint peeling.

We can color according to RAL and Pantone color cards or customer samples.

The commonly used prepainted aluminum coil width is 914mm. We usually use navy blue color coated aluminum coil, and sometimes white gray, medium gray, and iron gray. The color selection is usually customized according to customer requirements. The thickness of the pre painted aluminum coil for roofing is 0.8mm~1.5mm, but we use 0.9mm~1.3mm more frequently. We will not use the very thin and thick color coated aluminum coils.

The price of prepainted aluminum roof coil fluctuates every day, depending on what material, size and thickness you need. So if you are interested in the painted aluminum coil for roofing, please contact us via email or whatsapp, you can send us your sample, or we can deliver sample free to you, we are willing to help you now!

Nydia

Nydia

Sales Manager

Sales Manager