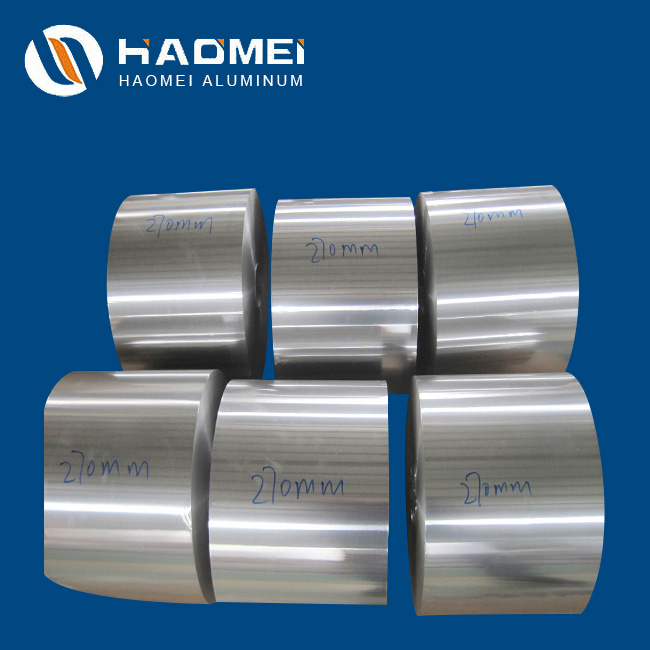

Plain and Pro-people Coil Aluminium 1060

April 9, 2018

Coil aluminium 1060 is one of the most common type of coil aluminium, yet many newly-comers of the industry feel confused and disoriented, for there are so many types with numerous usages which usually mix with each other. Today let’s talk about plain and pro-people alloy 1060.

Coil aluminium 1060 is a plain one among the big coil aluminium family. It contains over 99.6% aluminum, and thus is also called pure aluminium product. Because of its simple composition 1060 is easy to be made. With long manufacturing history humans have developed mature processing technology for coil aluminium 1060, which makes it much cheaper than many aluminum alloys. That’s one of the reasons why it is so widely used. 1060 has big percentage of elongation and strong strength of extension, totally meeting requirement of normal processing like punching and extending. With perfect plasticity, corrosion resistance as well as electric and heat conductivity, it can be pressed, extended, bent or welded (gas welding, atomic H welding and contact welding, but not braze welding). Every coin has two sides. Good flexibility means unfavorable hardness. Coil aluminium 1060 has bad machinable property and cannot be over treated by heat.

We refer to Coil aluminium 1060 as being pro-people because it’s so widely used in our daily life. At home it’s part of cupboards, decoration articles, light bases, electric fans and solar power heaters. Outside on the street it turns to be road signs, advertising boards and factory walls. On our way to work it serves as bus body covers. For our office building it’s decorative walls. But all these applications have one thing in common–low requirement of material hardness. Low hardness is both advantage and disadvantage of coil aluminium 1060 by different judging standards. Haomei produces coil aluminium 1060 of 0.2-6mm thick and 1000-2000mm wide. Welcome to contact us at april@aluminumhm.com.

Nydia

Nydia

Sales Manager

Sales Manager