News

This is mainly used for introducing news about aluminum strip, aluminum coil, aluminum circle, aluminum slugs.

Can 5754 aluminum sheet be made into aluminum mirror sheet

Can 5754 aluminum sheet be made into alu mirror sheet? There are two methods to make an ordinary aluminium sheet into a mirror plate: polishing and anodizing. Theoretically all alloys of aluminum can be treated by these two methods, but the effect varies from alloy to alloy. Common mirror aluminum plates are mainly made of 1 series pure aluminum plates …

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum alloy

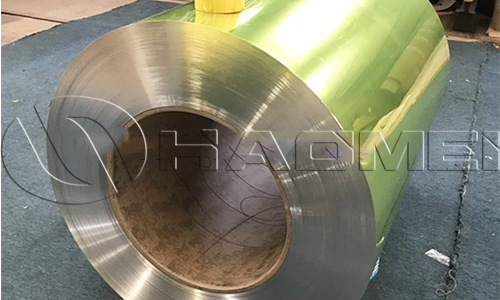

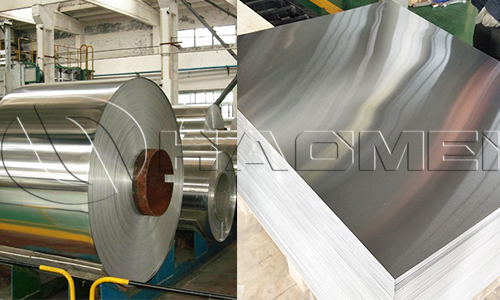

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum coil and sheet aluminium coil or strip covers 1xxx, 3xxx, 5xxx, 6xxx and 7xxx series and their all possible shapes. Here we deal with only the representative alloy of each series. 1050 aluminum coil is the representative of 1xxx series. In addition to the coil type, 1050 can also be made …

Differences between pure and alloy aluminum coil

A pure aluminium coil refers to 1xxx series of aluminium coil, like the 1070 aluminum coil for sale, while an alloy alu coil stands for alu coil rolls of all other series, including 3xxx, 2xxx, 4xxx, 5xxx, 6xxx, 7xxx and 8xxx, among which only 3 are the most frequently applied. 1xxx coil is known as the pure coil group because …

Possible disadvantages of anodized aluminum sheet

Anodized aluminum sheets are more frequently mentioned with its advantages, and it looks as if there are no disadvantages at all. Yet this is not always the case. Failures in any step of anodising process might lead to the following weaknesses of a pre anodized aluminum sheet. The first is transparency reduction. Aluminium sheets have their own transparency. The process …

Bronze anodized aluminum sheet used in building

Bronze anodized aluminum sheet has a hard adhesive film with outstanding hardness and wear resistance. With a solemn color similar to traditional wooden furniture, the sheet serves as a novel material in exterior and interior decoration of buildings. Anodizing technology overcomes the defects of traditional aluminum alloy surface treatment technology in terms of hardness and wear resistance, and also overcomes …

Top quality 3003 aluminum coil for letter

3003 aluminum coil for letter is a painted or anodized aluminium product with an alloy metal of manganese alloy. 3003 is the most widely used of all alloys. It is basically a commercial pure aluminium and is 20% stronger than 1100. It has good hardness, corrosion resistance but relatively poor anodizing property. Anodized 3003 aluminum sheets or rolls might have …

Food grade aluminum coil stock suppliers

Aluminum coil stock suppliers are not surprised by novel applications and demands from clients any more. Their products find applications in such a variety of industries that it’s extremely hard not to spot an aluminium product in a single day. As known to all, aluminum coil usually serves as a raw material for heavy industrial products like vehicles, planes, ships, …

Is 3003 aluminum coil used for beverage cans

3003 aluminum coil ranks top in popularity among Al-Mn aluminium sheet rolls which serve as an excellent material for beverage cans. 3003 used to be used in beverage cans. Due to the manganese alloy element, it shows excellent anti-rust properties. Aluminum will form an oxide film on the outside in the air, namely aluminum oxide, which prevents aluminum from being …

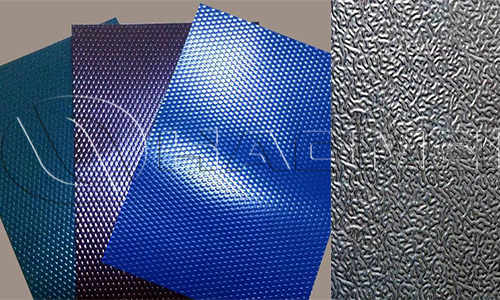

Surface treatment methods for aluminum stucco sheets

Surface treatment methods for an aluminum stucco sheet include mill finish, anodizing and color coating. Each has its own functions and applications. Mill finish stucco embossed aluminium sheets have no extra treatment for the surface. This method is applied to stucco sheets for general uses, like fridge inner wall cladding, air conditioners, heat sinks, pipe insulation etc. The thickness ranges …

Embossed aluminum coil exported to Turkey UAE Vietnam Indonesia

In recent years, the use of embossed aluminum coils has become more and more extensive, such as embossing of heating pipes, power plants, chemical plants, packaging of various mechanical equipment, tank equipment, and so on. Aluminum coil is also called aluminum skin in these applications, mainly divided into embossed aluminum skin, anti-corrosion aluminum skin, anti-rust aluminum skin, and alloy aluminum …

3mm brushed aluminium plate

The “3mm” of a 3mm brushed aluminium plate refers to the thickness of the plate. This number is relatively big for most brushed aluminium plates are only around 1mm thick. Alloys of the plate cover 1050, 1060, 1100, 3003, 3004, 2014, 2024, 5052, 6061 and 7005, but the most frequently applied are 1xxx, 3xxx and 5xxx series. The color of …

Is 1050 aluminum circle for cookware cold rolled or hot rolled

1050 aluminum circle is a common product used in cookware. Should it be cold rolled or hot rolled? Which process is better for cookware products? Let’s take a look at the differences between cold rolling and hot rolling first. Cold rolling is rolling below the recrystallization temperature, and hot rolling is rolling above the recrystallization temperature. When we speak of …

Nydia

Nydia

Sales Manager

Sales Manager