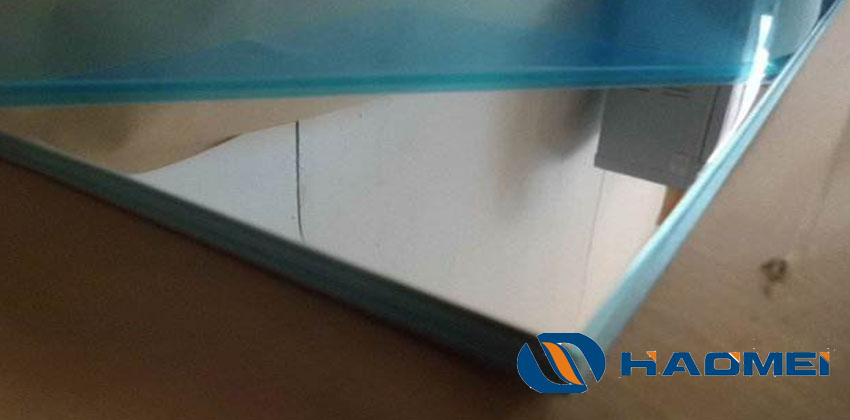

Mirror Finish Aluminum Sheet Metal Used as Cell Phone Shell

September 13, 2018

Mirror finish aluminum sheet metal can be applied in many industries, among which the most familiar to us is cell phone shell. Aluminum mirror sheet usually has alloys of 1050, 1060, 1070, 1100, 3003, 5005 and 5057 as its raw materials. As a relatively high end product, cell phone shells are generally made of 3xxx and 5xxx aluminium base sheets that perform better mirroring effect after being finished. Superior sheets have a reflectivity of 95% and more. The reflectivity keeps stable and long. While being used as cell phone shells, however, aluminum mirror sheet defeat its competitors not by high reflectivity but unique line effect.

Cell phones are becoming thinner and thinner, lighter and lighter to cater for fashions in global market. Among all easily available metals, aluminum proves to be the lightest with satisfying mechanical properties. It weighs only less than half of iron and one third of copper, beating the two competitors effortless by such an endowed advantage. It can be rolled into such extreme thicknesses that the thinnest aluminum foil is only several micro meter thick. It has such a good anti-corrosion property that even plain sheets last years. Mirror finish aluminum sheet metals have been treated by an anodizing process, which aims to strengthen their corrosion resistance and water-proof property. As cell phone shells, the metal does not get rusty in spite of long-term exposure to sweat. Boasting medium strength and good tensile strength, it withstands exterior shocks and can be coated with colors of other metals or natural colors to create various styles. The biggest advantage, however, proves to be mirror finish aluminum sheet price. Owing to the fact that the industry has developed mature technology and processing systems, mirror finish aluminum sheet metals can be obtained at much lower cost than steel, not to mention copper.

Nydia

Nydia

Sales Manager

Sales Manager