How to Judge Quality of Aluminium Discs Circles

February 12, 2019

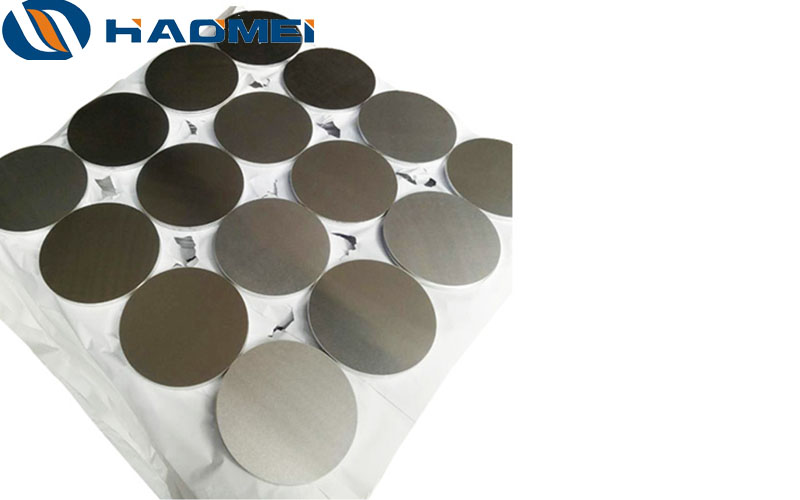

An aluminum circle is one of the most popular semi-processed aluminum products in global market. Aluminium discs circles are made into various end products like food cans, bottle caps, strainers, cooking pots, kettles, aluminum buckets and so on. Then as a purchasing green hand, how should you judge the quality of aluminum circle samples you have received from suppliers that have been picked out after an exhausting comparison? Among leading China aluminum circle manufacturers, Haomei advises you to pay attention to at least three points: purity, precision and further processing properties.

Purity refers to whether the ratio of chemical elements of a piece of aluminum circle is consistent with its alloy number. Take 1070 aluminium discs circles for example, the disc should contain at least 97% of pure aluminum, or else it would be regarded as impure. Some alloys (like 3003) have a more complicated composition, and you should make sure that the content of each element is appropriate enough. Precision means that the size of an aluminum circle must be precise enough, including its thickness, diameter and edges. Precision is regarded as an important factor in judging the quality of aluminium discs circles. Further processing properties are a little more complex, for a circle might be processed into various utensils. Generally speaking, aluminium circles for utensils will go through further processing methods like deep drawing and spinning, in which the ear rate becomes an obvious factor reflecting quality of the circle. The lower the rate, the better the circle. What’s worse, some inferior discs even get pierced during further processing. Therefore, it’s crucial to test the sample before you deciding to cooperate with an aluminum circle supplier.

Nydia

Nydia

Sales Manager

Sales Manager