How to extend service life of black aluminum trim coil

August 5, 2019

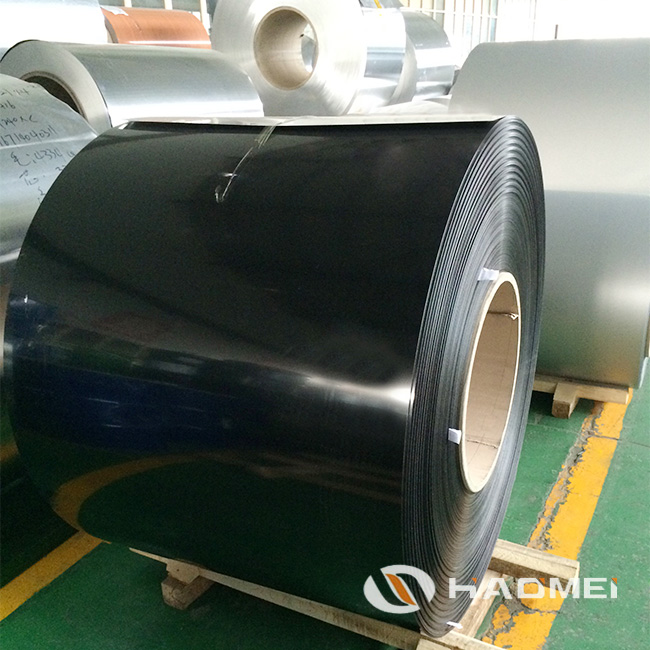

Boasting a mature color, a delicate surface and excellent corrosion resistance, the black aluminum trim coil becomes popular in building and decorative industries. Reasonable applying tips help to extend service life of the coil.

Tip one, if the black aluminum trim coil is to be put into operation, the temperature should not be overheated or too cold. This may be confusing, but just consider use it for normal purposes at normal temperatures. Natural temperaturs are ok. If it is used as a roofing material, the height should not be lower than 10 degrees.

Tip two, no matter it is used for adevertising or roofing, check in time to ensure that the aluminum trim coil material has no wear or tear, and that it can be used normally. Only under these conditions can the coil last long enough as expected.

Tip three, the bolt head of the fixed color coated aluminum coil should be sealed with a waterproof material to prevent rain from rusting the material.

Tip four, the ambient temperature of color-coated aluminum coil processing should be above 7 °C. The gap of the processing roller system should be adjusted according to the thickness of the black aluminum trim coil, and the foreign objects on the roller surface and the pallet should be removed. In case of paint stripping on either or both sides of the coil, the cause should be identified and the measures must be taken before processing can continue.

All delicate products need to be treated with caution, and the aluminum trim coil is of no exception. If you want to ensure quality of the coil in further processing and application, please follow tips above.

Nydia

Nydia

Sales Manager

Sales Manager