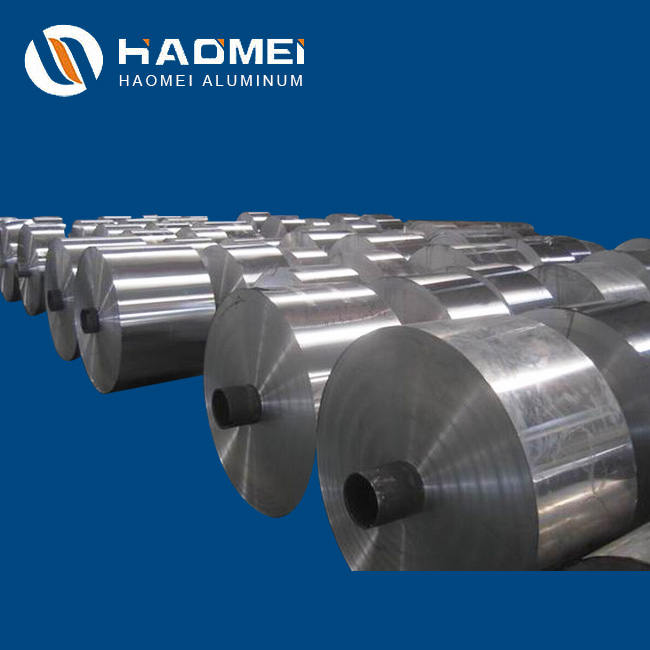

Haomei Coil Aluminum for Bottle Caps

March 2, 2018

As a new material for bottle caps, coil aluminum is featured by its simple beauty and an extra function of preventing imitations. Manufacturers can make their own unique cap designs for bottles of each series of products. This helps to build their own brand image. Manufacturers can even apply high-tech process in production of their bottle cap, which effectively avoids possible imitation from competitors. Therefore, coil aluminum is more and more wide used as raw material of bottle caps for beverages, wine&spirit, cosmetics and pharmaceutics.

Haomei has series 1, 3, 5 and 8 coil aluminum, all of which can be used for bottle caps. The most frequently used types are 1060, 3140, 5052 and 8011. Our coil aluminum for bottle caps have the following advantages. First, the width and thickness are controlled in strict accordance with process card, thus the chance for random error is very small. Second, the surface is smooth and even, without usual flaws like cracks, air bubbles, obvious and invisible lines or unnecessary materials which might be pressed into the coil by accident. Third, we follow strict inspection procedures during and after the manufacturing process. In the punching process inspectors check the quality of at least 1 piece for every 3 pieces of coil. When the coil pieces come to the finishing part, they are inspected one by one. This helps to guarantee the qualification of each piece of our product. Fourth, Haomei has strict and detailed rules for slice quality control, making sure that there are no quality problems such as burrs, knife marks and corrugated edges. Welcome to contact april@aluminumhm.com for more information.

Nydia

Nydia

Sales Manager

Sales Manager