Features of aluminum checker plate 6061 t6

August 7, 2019

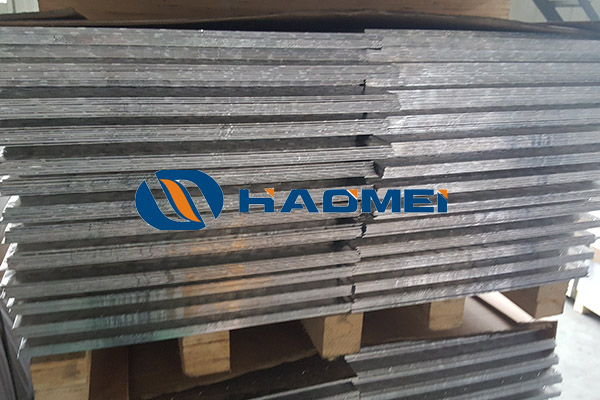

The aluminum checker plate 6061 t6 has been continuously rolled or cold-formed. Its hardness and straightness are far superior to other similar ceiling products. The surface of the plate is evenly and consistently colored, the texture is clear and realistic, and the style is unique. Aluminum checker plate 6061 t6 is extremely durable and resistant to corrosion. Its lines are bright and tidy, with distinct layers, reflecting the simple and modern style. It can be matched with various colors and hanging heights to create a beautiful and generous shape and a changing color space.

In the 6061 aluminum alloy plate, aluminum alloys accounted for 97.9%, magnesium contained 1%, niobium accounted for 0.6%, and 0.28% copper and 0.2% chromium (Chromium). In all aluminium alloys treated by remote control models, we often see those of “T6” heat treatment. A “T6061-T6” heat-treated aluminum alloy can have even higher “yield strength” and “tension” than the 7075 aluminum alloy (refer to the table below), but in the “scrap force” , it is lower than the 7075. Therefore, after the “T6” heat treatment, the “yield force” and “tension” of the aluminum checker plate 6061 can be greatly improved, but the increase in the “shearing force” is small, and the technique of this heat treatment is equally applicable to the materials of 6061 and 7075.

Featured by even bright colors, clear natural colors, smooth line, generous shapes, strong harndess, excellent weather resistance and long service life, the aluminum checker plate 6061 t6 is processed into anti-skid panels and wall cladding materials for commercial buildings, airports, express railways, subway stations, stadiums, schools, parks, meeting rooms, villas, offices, hospitals, official buildings, pavilions, tunnels, homes, cinemas, hotels, bank buildings, shopping malls, restaurants, libraries, parking lots, pedestrians, toll stations, refueling stations, facade signboards, 4S shops, squares and so on.

Nydia

Nydia

Sales Manager

Sales Manager