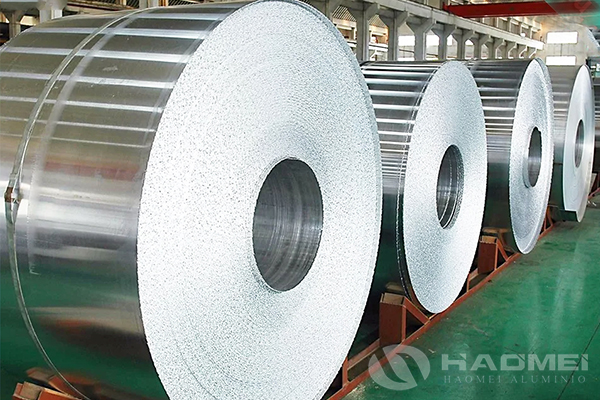

Factory price aluminum coil 5182 3004 h24

June 10, 2020

The thickness for aluminum coil 5182 and 3003 h24 ranges between 0.1mm to 8mm. As a beverage material they are usually less than 2mm thick. Width is 100mm and above. Both of the two aluminum alloys are featured by good hardness, corrosion resistance, forming property and elongation rate, applied in vehicle and construction parts.

Aluminum coil 5182 belongs to the group of high magnesium aluminium alloy. It is a heat-treatable alloy with outstanding erosion resistance, cutting property, welding property and cold working property. With a medium strength among aluminium alloy members, it boasts a glossy surface after being polished. 5182 incorporates silicon and a little more magnesium than 5052, which improves its welding property in a way. Therefore, it’s an appropriate material for beverage can pull rings. In addition, 5182 alu coil is made into plane oil tanks, oil tubes and mechanical parts for vehicles and ships.

The similarity aluminum coil 3004 h24 shares with 5052 is the application in beverages. Different from 5052, 3004 coil serves as a beverage bottom and body material. It’s pale before 5052 in either strength or corrosion resistance, but it overshadows 3003 in hardness and tensile strength, applied in aluminium roofing, wall cladding, color coated substrate coil, shutters, lamp heads, decoration, printing, packaging, building, transport vehicles, chemical containers, electronic units and so on. As a material for beverage can bodies, 3004 alu coil is safe, light and beautiful. The prominent anti-oxidation property of 3004 aluminium alloy perfectly prevents oxidation and erosion of contained beverages to beverage cans. Another advantage of 3004 alu coil falls on its high recycling rate. Take beverage cans for example. There are numerous papers analyzing methods of recycling aluminium cans in a more efficient way, which demonstrates prosperity of aluminium recycling industry and popularity of environmental protection.

Nydia

Nydia

Sales Manager

Sales Manager