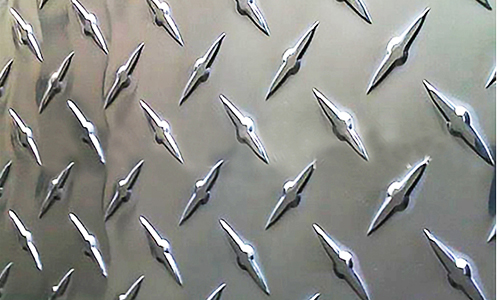

Diamond aluminum checker plate embossed

June 3, 2021

A diamond aluminum checker plate embossed is a checker plate of diamond pattern. It’s obtained by having a mill finished aluminum roll go through an embossing roller of diamond patterns. The roll comes out as a diamond aluminum roll, and then is cut into pieces of a given size. Diamond aluminum plate proves to be the second most popular checker plates of aluminium, after only five bar. It’s beautiful and anti-skid, and can be made of varied alloys with different hardness, elongation, tensile strength, corrosion resistance and bending rate, so as to meet application requirements in changeable cases.

Common alloys for the diamond aluminum plates include 1060, 1100, 3003, 5052, 5754, 5083, 6061, 6063 and 6082. Each of these alloys can be made into plates of varied tempers corresponding kinds of hardness and material fineness. For example, 6000 series of aluminum checker plates, including 6061, 6063 and 6082, are usually of T4 or T6 temper. The T4 state is that the aluminum plate is cooled after coming out of the machine, but not put into the aging furnace for aging. Thus T4 aluminum checker plates have lower hardness and better deformability, and are suitable for deformation processing such as later bending. The T6 state is water-cooled quenching, and the artificial aging temperature after quenching will be higher, and the holding time will be longer to achieve a higher hardness state. Therefore, T6 diamond embossed aluminum checker plates are harder and less suitable for bending. Other alloys, such as 1100, 3003, 5052 and so on, can only be of H or O state, which are poorer in hardness and mechanical properties.

Haomei supplies embossed diamond aluminum checker plates of 1.2mm to 8.0mm thick, 100mm to 1850mm wide, and 500mm to 16000mm long. Our checker plates are applied anti-slip flooring for cars, public places, stairs and interior decoration.

Nydia

Nydia

Sales Manager

Sales Manager