Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

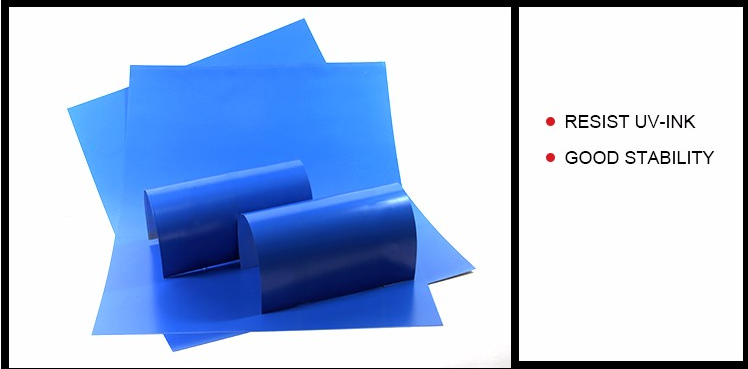

Color: violet,light blue or green

Thickness: 0.15mm-0.40mm

Spectral sensitivity: 830nm

Developing temperature: 24°C-26°C

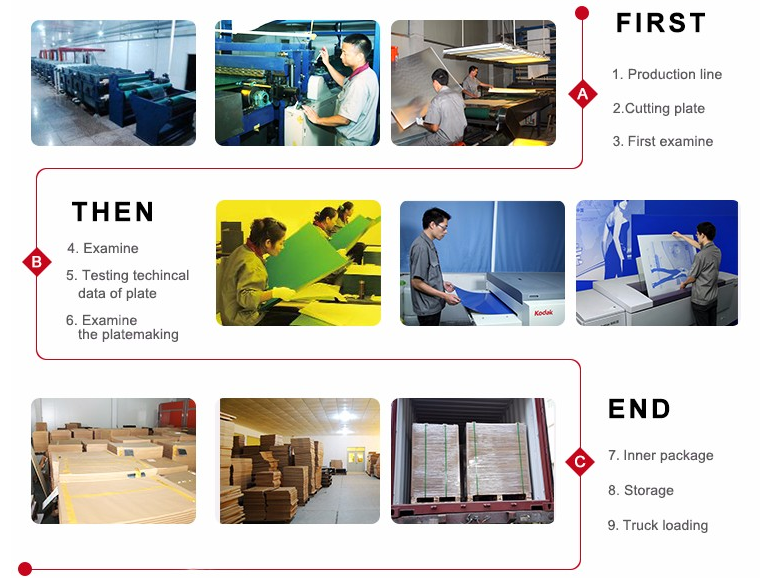

CTP Thermal plate is a special printing plate for thermal CTP plate setter. Controlled by computer, it is directly scanned by a 830nm laser and after suitably processed, placed on press for printing. CTP Thermal plate frees people from conventional printing films and related film making procedures. It shortens time for making plate and minimizes mistake chance by guaranteeing image exact reproduction.

enquiry| Features of CTP Thermal Plates | |

| Performance | Excellent dot reproduction, stable performance,

big latitude |

| Run length | Unbaked: 100,000 impressions;

Baked: 150,000 impressions |

| Cost reduction | High-speed plate, good ink-water balance,

quick inking, high usage rate of printing ink. |

| Suitability | Compatible with mainstream thermal platesetter and plate processor, super adaptability |

| Cost-effective | higher |

| Technical Parameters of CTP Thermal Plates | |

| Spectral sensitivity | 830nm |

| Laser energy required | 130~150mJ/cm2 |

| Resolution | 1%-99% @200lpi.Suitable for FM screen |

| UV ink adaptability | Plates need to be baked |

| Baked plate

of conditions |

230°C-250°C, 5-8minutes (Special gum should be used with baked plate ) |

| Safelight | 2 hours under the fluorescent light and white light.

12 hours under the yellow light. |

| Transport and storage | Keep CTP Thermal plates flat in packaging,

Temperature should be between 5 °C and 30 °C (10- 26°C best) and humidity below 55% (40 -70% best). |

| Maxim stacking height | 1.2m |

| Shelf life | 12 months |

| Developing temperature | 24°C-26°C |

| Developing time | 20s-30s |

| Dynamically added | 130ml/m2 |

| Static added | 110ml/hour |

| Brush rotated speed | 90-100rpm |

| The quantity

of plate flushing |

1800 m2-2500m2 |

| Matters Need Attention for CTP Thermal Plates | |

| 1. CTP Thermal plates get scratched more easily than traditional ps plates, and therefore should be handled gently with care to avoid striking, folding or falling.

2. CTP Thermal plates should be unpacked in yellow light or room light; the recommended plate-making room light is also yellow. Correct parameters must be set, developer should be replaced in time. |

|