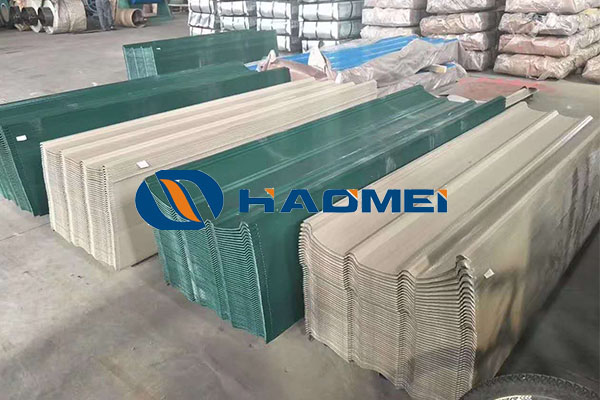

Colour coated aluminum sheet roofing sheet features

July 26, 2019

The colour coated aluminum sheet is used for roofing because of its attractive outlook, sustainable corrosion resistance, strong hardness, convenient installation, excellent fire-proof performance and good recyclable property. A colour coated aluminum sheet is obtained by coating the base sheet with paints of given colors. After being treated specially on the surface, it lasts three decades without color decay or corrosion.

1. Advanced technology and high folding resistance

The raw materials of coluor coated aluminium roofing sheet pieces, such as aluminum, plastic and adhesive, are all high-quality products that are further processed by advanced composite technology. They do not get influenced by natural climate conditions like changes in wind pressure, temperature, humidity and so on. No bending, deformation and expansion will occur.

2. Rich in color, strong decoration

The colour coated aluminum roofing sheet has a realistic material feel and a fresh natural beauty. Its color, shape and pattern on the surface can be done at will, for the sheet is adaptable to various paints and processing methods. This enables suppliers to supply varied sheets according to an individual customer’s needs in personality and beauty.

3. Strong weather resistance and good color stability

The paint pattern of the colour coated aluminum sheet is formed by coating and high temperature baking, boasting high gloss retention, good color stability and minimal change in color difference.

Based on the product advantages and characteristics of the color coated aluminum roofing sheet, we can easily find that the performance of the aluminum coil is very stable, not easy to be corroded, the unit volume is light. At the same time, its color is also very rich, in the decoration and decoration industry has played a very good sense of decoration, beautiful, with more beautiful experience.

Nydia

Nydia

Sales Manager

Sales Manager