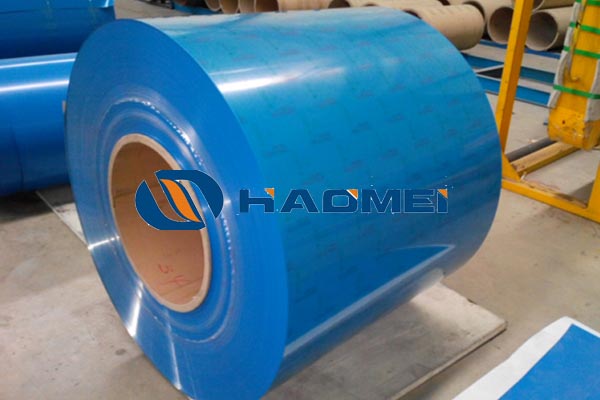

Colour coated aluminium sheet and coil used for windows

July 5, 2019

The rich color scope and excellent mechanical properties make colour coated aluminium sheet and coil an ideal construction material for windows, doors, platforms, wall cladding, convention centers, container roofs, outdoor sunshade aluminum shutters, European rolling shutter doors, high-grade interior and exterior wall aluminum-plastic panel industry, new roofing, wall coverings, ceilings, ceilings, roofing enclosures, various new aluminum materials and honeycomb panel products.

While being used in windows, the colour coated aluminium coil and sheet serves as both an interior and exterior material, for it withstands corrosive material from inside the room and natural conditions like sunshine, frost and rain. This poses a bigger challenge for window materials than those simply for indoor objects. The performance of a color coated aluminium sheet and coil first depends upon its base material, usually 3000 and 5000 series of aluminium, the hardness and corrosion resistance of which are excellent. In addition to the base material, paint quality plays a equally important role. Regular paints for colour coated aluminium include pe and pvdf, each with its own process and features. The polyester coated aluminum coil coating can be defined as matt and highlight during the manufacturing process. Polyester coating gives the material a good color, more authenticity, and better blending with the surface of the material, so the aluminum window surface has good smoothness and gloss. The fluorocarbon-coated aluminium coil is even more excellent, and the molecular structure inside the fluorocarbon material is reorganized, giving the color coated aluminium coil more functions.

Windows made of colour coated aluminium sheet and coil rolls are light in weight, strong in corrosion resistance, adaptable in decoration style and long in service life. In addition to thin sheets and rolls, aluminium extrusion for windows is even more popular, becoming an irreplaceable part in modern building construction.

Nydia

Nydia

Sales Manager

Sales Manager