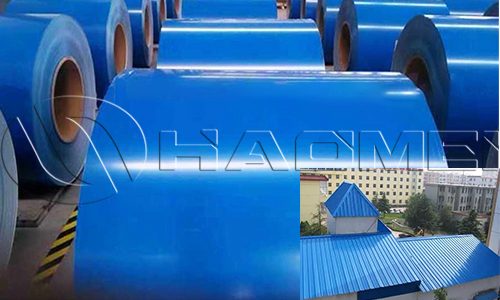

Color coated aluminum coils for roofing sheets

July 9, 2021

Color coated aluminum coils for roofing sheets are of alloys 1050, 1060, 1100, 3003, 3004 and 3105. Although there are 6 candidate alloys, only 3003 and 3004 are the most popular. 1050, 1060 and 1100 are weaker in either hardness or corrosion resistance. They are suitable for roofing sheets expected to last only years, especially when they are coated with PE paint. PVDF coated aluminium roofing coil rolls usually last much longer, over 20 years with an ideal thickness. The tempers of the coils include H46 and H44, and the thickness ranges from 0.3mm to1.5mm, and width 600mm to 1250mm.

The color coated aluminum roofing sheet coil is featured by low weight, good corrosion resistance and outstanding processing ability. In comparison to stone and pottery roofing sheets, aluminium sheets are much lighter, which indicates convenient installation and maintenance. Good corrosion resistance is an exclusive advantage of aluminium coil over other roofing materials. What’s more, the color coated aluminium coils for roofing sheets have durable and weather resistant coating of resin paints. This extends their service life substantially. Last but not least, the coated aluminum rolls will have to be bent and perforated before being made into roofing sheets, and the sheets need to be drilled for installation. 1000 and 3000 series of aluminium coils have proper elongation and hardness, just perfect for such processing methods. That’s why aluminium roofing sheets become increasingly popular.

Haomei guarantees the minimum coating thickness of 18um for pe and 25um for pvdf. The color of the coil can be customized. Usually we follow the color card of RAL9006, RAL9016, RAL9007, RAL7039, RAL7035 and RAL7021. In addition, the bending hardness, pencil hardness, boiling resistance and service life can be guaranteed, too. The price of the color coated aluminum coils for roofing sheets has been rising with that of raw material and manufacturing cost, and it fluctuates daily. Please contact us for an instantly price!

Nydia

Nydia

Sales Manager

Sales Manager