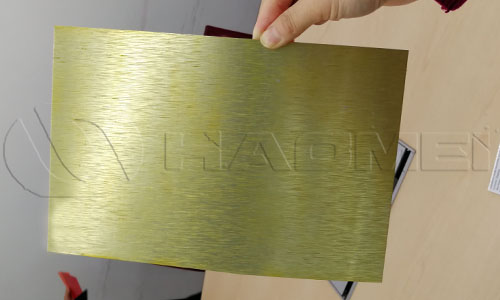

Brushed aluminium sheet for cell phone shells

August 6, 2020

The application of brushed aluminum sheets in cell phone shells is not novel any more. As long as years ago, Apple took the first step to adopt brushed aluminium to case its batteries, attracting public attention to the once unknown brushed aluminium. The bold creativity of Apple designers is based on excellent performances of brushed aluminium composite sheet: light weight, fast heat dissipation, fashionable appearance, and long service life.

Many grades are suitable materials for a brushed aluminum sheet metal, the most popular of which cover 1050, 1060 and 1100. It’s not that aluminium alloys can not be made into brushed sheets, they are simply harder in strength and less likely to boycott shock impacts. In the process of using brushed aluminum to process the mobile phone case, we usually process the plate with anodizing processing technology to form an oxide protective layer on the surface, and this protective layer allows us to observe every tiny silk mark. The oxidation coloring process can be carried out if you need colors, including the so-called “luxury gold” and “rose gold” which catch on now. The thickness of Haomei brushed aluminium sheet for labels and electric housing is 0.25mm to 1.0mm and the width up to 1250mm. The coils can be processed into strips and sheet pieces as required.

A brushed aluminium sheet have the following advantages as a phone shell material. First, it has rich colors and soft metal texture, so more and more metal shells for electronic products adopt wire drawing process to achieve beautiful and practical effect. Second, delicate brushed texture and different aesthetic feeling. The continuity of the surface film layer at 90° or 180° angle is no burst or detachment, and the brushed texture is delicate and fashionable, making the metal matte shine in the fine hair Silk luster. Third, compared with traditional anodic anodized aluminium sheets, it is more resistant to scrubbing, and alkaline cleaning solution is especially obvious. The patented anodic oxidation technology solves the stamping burst problem with traditional anodic oxidation. It is anti-fingerprint and has strong metallic feeling in mobile phone case application. Fourth, the anti-aging time of brushed aluminum plates is 6-8 times that of traditional anodizing, keeping shells of cell phones new even after years of using.

Nydia

Nydia

Sales Manager

Sales Manager