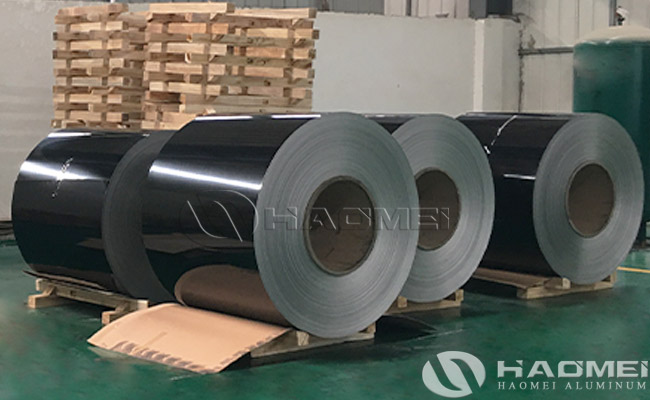

Black Prepainted Aluminum Coil

March 25, 2025

Black prepainted aluminum coil is a color coated aluminum coil with a black paint finish used primarily in architectural, decorative, appliance and other industrial applications.

The coatings of black pre-coated aluminum coils are mainly divided into two categories: fluorocarbon coating (PVDF) and polyester coating, which differ in performance, life and application scenarios.

- Fluorocarbon coating (PVDF)

– Coating material:

Mainly based on polyvinylidene fluoride (PVDF) resin, which can be copolymerized with other fluorine-containing monomers to form a polymer structure.

– Characteristics:

– Super weather resistance: The fluorocarbon coating has a tight molecular structure, is resistant to ultraviolet rays, acid and alkali, and salt spray, and can withstand harsh climates (such as high temperature, humidity, and acid rain).

– Durability: The service life is up to 20-30 years (fluorocarbon coating), the coating does not fade or fall off, and is suitable for long-term outdoor use.

– Decorative: A variety of black tones (such as matte black, glossy black, metallic black) can be adjusted, in line with international color cards (such as RAL, Pantone).

– Mechanical properties: impact resistance, wear resistance, and bending resistance, coating thickness ≥ 25 microns.

– Application standard:

Comply with the national standard YS/T 431-2009, impact resistance test (50kg/cm²) without cracks or paint peeling.

- Polyester coating

– Coating material:

Polyester resin is used as the base material, with low cost and mature technology.

– Features:

– Moderate weather resistance: Weaker than fluorocarbon coating, suitable for indoor or light outdoor environment.

– Service life: about 10-15 years, slightly inferior color stability, but obvious cost advantage.

– Decorative: Black color can be adjusted, but long-term outdoor use may cause slight fading.

– Coating thickness: ≥18 microns.

– Applicable scenarios:

Indoor decoration, home appliance panels, short-term outdoor facilities and other fields that do not require extreme weather resistance.

Application fields of black painted aluminum coils

Due to its excellent performance and aesthetic characteristics of black tones, black color coated aluminum coils are widely used in many fields:

- Architectural decoration

– Application scenarios:

– Curtain walls and facades: Fluorocarbon-coated black color aluminum coils are used for high-end building curtain walls, with strong weather resistance, solemn black tones, and suitable for modern style buildings.

– Indoor decoration: ceilings, partitions, fireproof panels, etc., polyester-coated black aluminum plates are low-cost and have uniform decorative effects.

– Public facilities: Decorative panels in public places such as subway stations and airports are corrosion-resistant and easy to clean.

– Advantages:

– The black coating can imitate the texture of stone and wood grain (through printing technology), reduce costs and enhance design sense.

– In line with the color matching of the international color card, the black series of different shades can be customized to meet personalized needs.

- Electronic appliances

– Application scenarios:

– Computer cases and electrical panels: The black coating enhances the texture of the product, resists impact and fingerprints, and enhances durability.

– Smart home devices: such as smart speakers and home appliance housings, black tones have a strong sense of technology and are easy to clean.

– Advantages:

– Polyester coatings are low-cost and suitable for mass production; fluorocarbon coatings are used for high-end products (such as outdoor electronic devices).

- Lighting and furniture

– Application scenarios:

– Lighting housings: Black aluminum coils can be used with LED light sources to enhance light efficiency, are resistant to high temperatures and are not easy to change color.

– Furniture finishes: Black aluminum plates with imitation wood grain and stone grain are used for high-end furniture (such as dining tables and cabinet doors), which are light and easy to maintain.

– Advantages:

– Textures such as wood grain and stone grain can be customized, combining the durability of metal and the beauty of natural materials.

- Industry and energy

– Application scenarios:

– Solar reflectors: Black coated aluminum coils are used for the back panels of solar collectors to absorb heat and reduce reflection interference.

– Air conditioning ducts: Corrosion-resistant and anti-aging, suitable for humid environments.

– Transportation: Black coated parts for high-speed rail and automotive interiors, lightweight and wear-resistant.

– Advantages:

– The weather resistance of fluorocarbon coating can withstand complex outdoor environments and extend the life of equipment.

- Other fields

– Advertising and logos:

– Black color aluminum coils are used for outdoor billboards and road signs. The black tone has high contrast and clear information.

– Packaging materials:

– Food-grade black coated aluminum coils are used for packaging containers, which are corrosion-resistant and have good sealing.

Precautions for choosing black color coated aluminum coils

- Coating type selection:

– Fluorocarbon coating: preferred for outdoor or highly corrosive environments (such as coastal areas and industrial areas).

– Polyester coating: suitable for indoor or short-term outdoor use, cost-sensitive scenarios.

- Thickness and specifications:

– Common thickness: 0.25mm-4.00mm, selected according to the purpose (such as 0.5-1.0mm for decoration, 2.0mm or more for structural parts).

- Color modulation:

– Can be customized according to international color cards such as RAL and Pantone to ensure color consistency.

- Supplier qualifications:

– Choose manufacturers that meet the YS/T 431-2009 standard to ensure that coating adhesion, impact resistance and other indicators meet the standards.

Black prepainted aluminum coils have become the preferred material in the fields of construction, electronics, furniture, etc. due to their high weather resistance, diverse decorative properties and lightweight characteristics. When choosing, it is necessary to reasonably match fluorocarbon or polyester coatings according to the use environment (indoor/outdoor), budget and life requirements, and pay attention to the supplier’s process standards and color card customization capabilities. If you need to know more about the specific model or price, you can provide more detailed demand information.

Nydia

Nydia

Sales Manager

Sales Manager