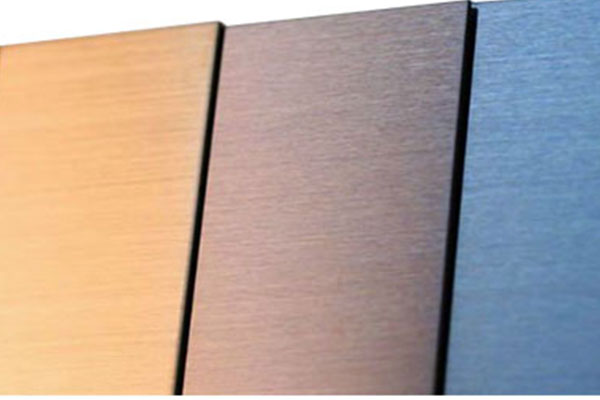

Features of an anodized colored aluminium sheet

November 1, 2019

Features of an anodized colored aluminium sheet is as below.

High Hardness

The hardness of the pure aluminum oxide film is higher than that of the aluminum alloy oxide film. Generally, its hardness is related to the alloy composition of aluminum and the technical conditions of the electrolyte during anodization. The anodized film is not only high in hardness but also has good wear resistance. Especially the surface layer porous oxide film has the ability to adsorb lubricant and further improve the wear resistance of the surface of the colored anodized aluminum plate.

Strong Corrosion Resistance

The strong corrosion resistance of an anodized sheet results from the high chemical stability of the anodized film. The anodized film of pure aluminum sheets has been tested to have better corrosion resistance than that of aluminum alloy sheets. This is because the alloy composition is mixed or the metal compound cannot be oxidized or dissolved, and the die-cast aluminum oxide film is discontinuous or the voids are formed, so that the corrosion resistance of the oxide film is greatly reduced. Therefore, the film obtained by anodizing generally goes through a sealing treatment to obtain a stronger corrosion resistance.

Strong Adsorption Capacity

The anodized film of a colored anodized aluminum sheet has a porous structure and a strong adsorption capacity. Therefore, filling the holes with various pigments, lubricants or resins can further improve the protection, insulation, wear resistance and decorative properties of the aluminum products.

Good Insulation Performance

The anodized film of aluminum sheets does not have the conductive properties of metals, and becomes a good insulating material.

Strong Heat Insulation and Resistance

This is because the thermal conductivity of the anodized film is much lower than that of pure aluminum sheets. The anodized film can withstand temperatures of around 1500 ° C, while pure aluminum sheets can only withstand 660 ° C. In summary, an anodized colored aluminum sheet boasts a surface with excellent protective and decorative functions.

That’s why it is widely used in aviation, electrical, electronics, machinery manufacturing and light industry.

Nydia

Nydia

Sales Manager

Sales Manager