Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5005, 5052

Temper: O,H12,H22,H14,H16,H18, H24,H26

Thickness: 0.2mm-8mm

Width: 100-2650mm

Surface treatment: mill finish, mirror finish, clear

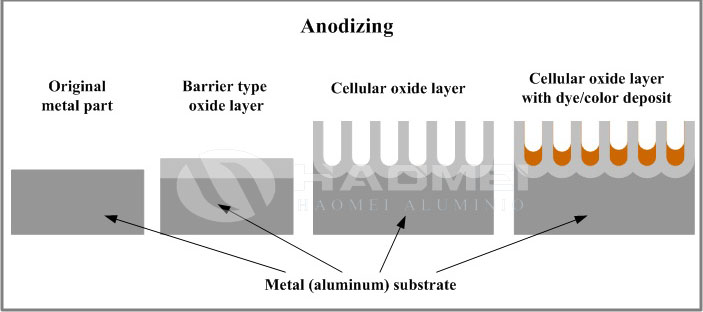

enquiryAnodized aluminum coil stock, falling on clear, mill finish, mirror finish, brushed and embossed surface treatment methods, deprives from the concept of aluminum coil anodizing which entails pre-anodizing aluminum coil and strip prior to fabrication.

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5005, 5052

Temper: O,H12,H22,H14,H16,H18, H24,H26

Thickness: 0.2mm-8mm

Width: 100-2650mm

Surface treatment: mill finish, mirror finish, clear

Type: sheet, coil, coil stock

Lead time: 7-25 working days

Payment terms: TT, LC, West Union, Kunlun Bank etc.

Haomei is an aluminum coil anodizing corporation itself, able to carry out anodizing of aluminium coil rolls of vaired surface treatment methods.

Relative product we supply: ordinary mill finish anodized aluminum sheet coil, clear mirror finish anodized aluminum coil stock, brushed anodized aluminium coil, anodized embossed aluminum coil (stucco, hammer, five bar, diamond, 1 bar etc.) Anodized frosted / brushed anodised aluminium coil thickness ranges include 0.3~0.6mm, 0.6~1.0mm, 1.0~1.2mm. The brushed hot-rolled gold 5005 5 series aluminum-magnesium alloy can be secondary processed width 85, 100, 150, 200, 300.

Application

Anodised aluminium coil rolls and sheet stocks find their applications in front desk/entrance, shelves, furniture, medical equipment, household appliances, building, marine building, aircraft planes, lamps etc.

Advantages

Haomei continuous anodized aluminum coil stock adopts German high-quality continuous anodizing process and introduces an automatic production line of aluminum coil continuous anodizing manufactured by core technology to implement continuous high-speed roll-to-roll large-scale production, including two 1.0mmX1250XC (thin plate), high-speed continuous anodizing automatic production lines, one 1.5mmX1600XC(wide and thick plate) high-speed continuous anodizing automatic production line, one 5.0mmX2000XC continuous anodizing automatic production line, an Italian aluminum coil high-speed wire drawing production line, an aluminum coil high-speed mirror polishing line, a flat panel slitter and other post-processing equipment. These enable us stand out of China anodized aluminum coil suppliers.  Our anodized coils offer unlimited lift potential and boast abrasion, corrosion, and radiation resistance as well as the ability to maintain electrical insulation properties. Further product benefits include longevity, lower operating temperatures, excellent heat transfer and lowered hot spots in magnetized systems. Our anodizing method utilizes a specialized process employing a 135 ft continuous anodizing line and duplex sealing with hot water and nickel. This technique produces a uniform coating with a consistent finish edge to edge and coil to coil. Anodized coatings are possible in thicknesses from .0004 in (400 VDC) minimum to .001 in, and color finishes are also available.

Our anodized coils offer unlimited lift potential and boast abrasion, corrosion, and radiation resistance as well as the ability to maintain electrical insulation properties. Further product benefits include longevity, lower operating temperatures, excellent heat transfer and lowered hot spots in magnetized systems. Our anodizing method utilizes a specialized process employing a 135 ft continuous anodizing line and duplex sealing with hot water and nickel. This technique produces a uniform coating with a consistent finish edge to edge and coil to coil. Anodized coatings are possible in thicknesses from .0004 in (400 VDC) minimum to .001 in, and color finishes are also available.