Aluminum Stucco Embossed Sheet Suppliers

October 10, 2018

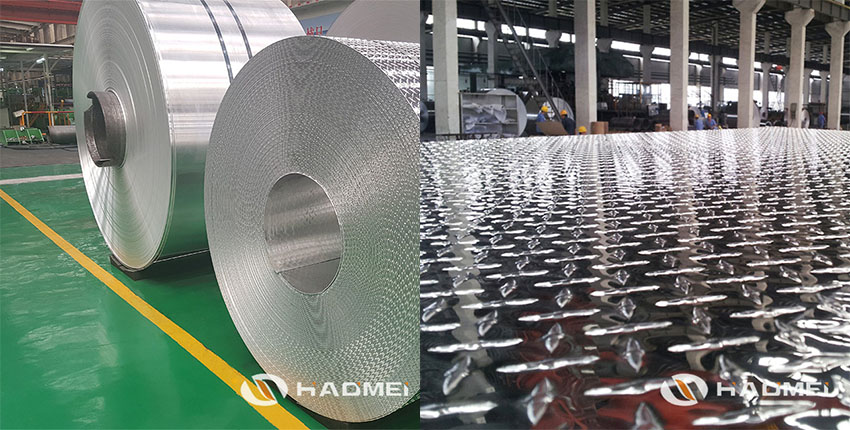

Aluminum stucco embossed sheet is a type of aluminum embossed sheet with stucco patterns. It’s obtained by rolling base aluminum sheets using a roller with stucco designs. Stucco embossed aluminum sheets cover a wide range of application, including lighting parts, reflective panels, wall cladding, interior decoration, ceilings, furniture, elevators, labels, cases, boxes, automobile decoration, domestic ornaments, home appliance (fridge panels, micro wave facial panels, sound equipment parts), military products, air planes, aircraft, satellites, machinery parts, mould, pipeline covering etc. Owing to extensive application areas of the sheet, aluminum stucco embossed sheet suppliers are springing up around the world.

Most aluminum stucco embossed sheet suppliers are integrated manufacturers of plain sheets, embossed sheets, anodized sheets and even mirror sheets, for the processing steps of these products overlap each other to different degrees. The production process of embossed aluminum sheets consists of raw material preparation, melting, casting, extruding and painting. Engineers should make a detailed calculation of element ratios in accordance with required alloys, then aluminum ingots and other metals are are placed into the melting oven for melting of these materials and removal of waste gases as well as solids. After being cooled, melted liquids come into a casting machine to turn into round bars of various specifications. The bars will further be extruded until they become aluminum sheets of desired thickness and size, during which corresponding heat treatment methods are adopted to different tempers required. At the same time, stucco patterns are embossed onto the sheet surface that must be anodized before being coated with paintings. Generally stucco embossed aluminum sheets are gray, but bright colors like red or blue are also available.

Nydia

Nydia

Sales Manager

Sales Manager