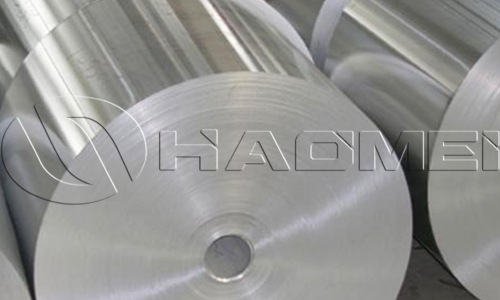

Aluminum strip alloys and applications

September 17, 2020

Aluminum strip alloys include 1060, 1100, 3003, 3004, 5052 and 8011. Applications cover aluminum-plastic composite pipes, cables, optical cables, transformers, heaters, shutters etc.

1060 aluminum strip stock contains more than 99.6% aluminum, and is also called pure aluminum strip. The typical use is transformer winding. The transformer aluminum belt is made of high-quality pure aluminum, which has the characteristics of high conductivity and softness. The thickness includes 0.05, 0.1, 0.15, 0.2, 0.3, 0.5, etc., and the conventional widths are: 50, 60, 80, 100, 120, 150, 300, etc. The electrical and thermal conductivity of aluminum is only lower than that of conventional metals of copper, and the electrical conductivity of metals is in order: silver, copper, gold, aluminum, nickel, steel alloy. Since the price of copper is much higher than that of aluminum, the current commonly used material for transformer belts is aluminum belt.

3003 aluminum strip is a common product in the aluminum-manganese alloy series. Better than having manganese alloy elements, this product has excellent anti-rust properties and is also called anti-rust aluminum strip. The 3003 thin aluminium strip can be used for KN95 mask strips, the specification is 3003-O, mill finish, the thickness is 0.4-0.5mm, and the width is 90-100mm. 3003 aluminum tape can also be used for luminous characters, and generally requires anodizing or color coating. 5052 aluminum has good forming and processing properties, corrosion resistance, candle resistance, fatigue strength and medium static strength. It is used to make blinds. 1100 aluminum tape is used for processing parts that require good formability and high corrosion resistance but do not require high strength, such as chemical printing plates, nameplates, and reflectors. 3004 aluminum strip can be used for all aluminum cans, lamps, etc. It is harder than 3004 and has stronger corrosion resistance.

Nydia

Nydia

Sales Manager

Sales Manager