Aluminum slug circle precision

January 25, 2020

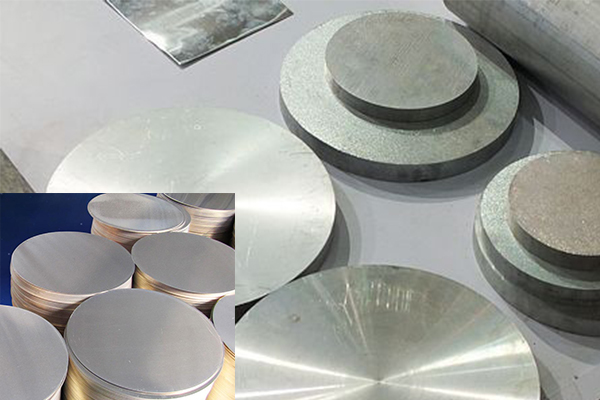

An aluminum slug circle refers to a small piece of round aluminum sheet, usually with a diameter of 100mm and below. The diameter of the smallest slugs are only 5mm. The thickness of aluminum slug circles ranges from 0.5mm to 5.0mm. Their precision is reflected in their purity level and size precision.

The purity of an aluminum circle slug is first determined by alloy melting technology, which depends on many aspects like furnace types and fuels. Round furnaces are more advanced than those of other shapes. Whatever kind of fuel it is for a furnace, a chimney should be equipped to provided to discharge the waste gas residues of the fuel. Lack of chimneys will result in production of low-quality aluminum wafer raw materials, for slag, bubbles and waste gas residues are all left in the aluminum water. The second factor is the content share of alloying elements such as manganese, magnesium, silicon and so on, the ratio of which is set by a strict range in the process of making aluminum alloying circle slugs, and these content shares directly determine the quality of aluminum round sheets. This is usually regarded as a core process by aluminum discs suppliers who will not share with each other.

The size precision indicates whether an aluminum slug circle has required thickness and diameter. In the first place, the circle must be even in thickness. If it’s 1mm thick on one edge yet 1.5mm thick on the other, it’s inferior in quality. Diameter accuracy proves to be equally important, for larger sizes will lead to a waste of raw material in further process of aluminum discs yet smaller sizes will result smaller finished products.

To sum up, an aluminum slug circle of high precision should be made of an alloy of a strict metal ratio and be of the perfect size as required. 1070 and 1060 aluminum circle slugs are our core products. Welcome to send inquires!

Nydia

Nydia

Sales Manager

Sales Manager