Advantages of aluminum roof coil over other roofing materials

February 6, 2020

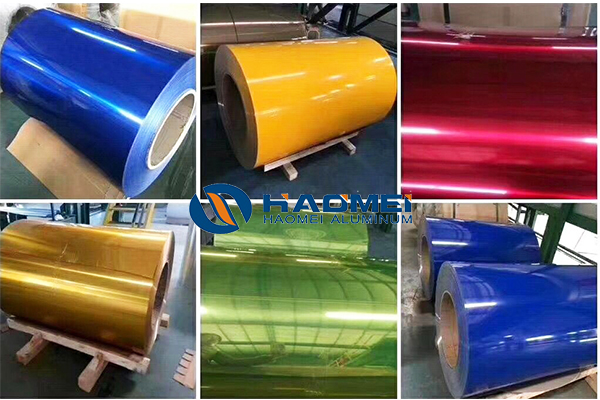

An aluminum roof sheet coil is a color coated roll with light weight, beautiful appearance and good anti-corrosion performance, and can be processed directly. Colors for the sheet coil are generally divided into gray, sea blue and brick red. In addition to roofing, the coated aluminum coil rolls are also applied in advertising, construction, home appliances, electrical appliances, furniture, and transportation industries. The coatings used in color-coated aluminium rolls are appropriate resins selected based on their application conditions, such as polyester silicon modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride and so on. Users can choose according to uses of the rolls.

Haomei supplies color coated aluminum coil for roofing of the following specifications.

Typical alloy states: A3004H24, A3004H26, A3003H24;

Typical thickness range: 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm;

Width: according to customer requirements, can be cut to any width within 55mm to 1600mm;

Color: thousands of colors , including blue, red, green, common silver grey, bright silver, champagne silver etc.

Aluminum roof sheet rolls have many advantages over other metal materials for roofing. First, it has a good temperature resistance. The melting point of aluminum is 660 degrees, and general temperatures fail to reach its melting point. Second, it’s environmental friendly. Chromium-free treatment liquid prevents the coating color from fading or changing, and the roller paint contains active chemical molecules that generates a protective layer on the surface of the material. Active chemical molecules are stable and easy to recycle, meeting environmental protection requirements. Third, the aluminum sheet coil is strong in corrosion resistance, because there is a tight oxide film on the surface. The film has strong adhesion, oxidation resistance, acid and alkali resistance, corrosion resistance, decay resistance, and ultraviolet radiation resistance. Fourth, the color of the roofing coil is uniform, permanent, even, delicate, soft and gorgeous. The coating process we adopt helps to avoid the individual color difference phenomenon in traditional spraying process. Fifth, an aluminum roof roll combines rigidness and toughness, and can be cut, slit, bent, pressed or drilled at will, fulfilling requirements in connection, fixing and edge compression molding of cut sheets.

If you want to learn about prices of aluminum sheet coil for roofing, welcome to contact us!

Nydia

Nydia

Sales Manager

Sales Manager