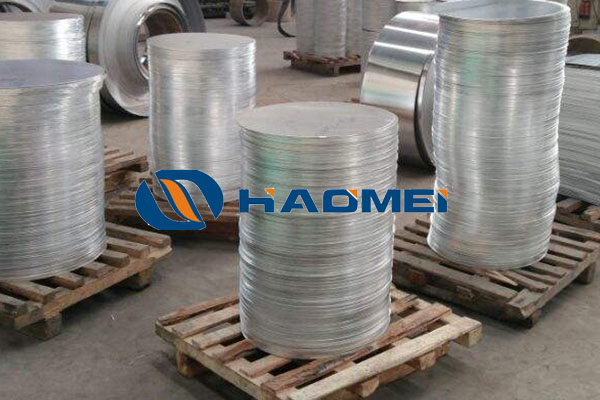

Aluminum disc blanks for cookware

May 14, 2019

Aluminum disk blanks for cookware have become a product type in the aluminum industry. It has been estimated that almost half of cookware items on the globe are made of aluminum disk blanks. The blanks refer to sheets or rolls which are later cut into aluminum disks of given diameters. Finished aluminum discs circles are processed into basins, pots, strainers, pot lids and so on. Owing to the fact that the processing steps entail stretching and pressing, the blanks must be strong and tensile enough, and series meeting such a requirement include 1xxx, 3xxx and 5xxx.

1xxx series of aluminum disk blanks include 1050, 1060, 1070 and 1100. These contain the biggest share of aluminium of all series, proving to be the softest as well. This makes it easier to bend or stretch them, but finished cookware is more vulnerable and gets deformed easily under influence of exterior forces. 1xxx is the cheapest series as a raw material for cookware, for its process is mature and simple. It’s more frequently made into cheaper cookware products that last only months before being discarded.

3xxx and 5xxx blanks have much better performances in both hardness and corrosion resistance. They contain more shares of other metals that make them stronger, and alloying metals like manganese and magnesium, greatly improves their corrosion resistance. Contacting water and food a lot, cookware does require a lot about corrosion resistance. Cookware of 3003 and 5052 lasts much longer than those of 1xxx series of aluminum disk blanks. Needless to say, they are more expensive.

Haomei supplies aluminum discs circles of all regular alloys for cookware, light parts, pharmaceutical tubes, battery shells, containing tanks etc. Welcome to contact us for more information!

Nydia

Nydia

Sales Manager

Sales Manager