Aluminum Coil Sheet VS Stainless Steel

March 8, 2018

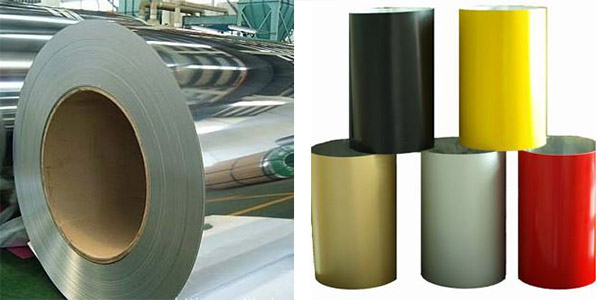

As known to all, compared to other metals, including steel, aluminum coil sheet boasts many competitive advantages and is more and more widely applied in many industries. However strong its development is, aluminum coil sheet has little chance to replace stainless steel. Today let’s make a comparison for the top two widely used metals.

First, stainless steel if of stronger hardness than aluminum coil sheet. Even the hardest aluminum alloy series, 8xxx, can not even compete with stainless steel in hardness. That’s the main reason why aluminum alloy will never replace stainless steel. Second, aluminum coil sheet can be processed with more surface treatment methods than stainless steel. Basic treatment methods for the former include grinding & polishing, sand blasting and surface drawing. There are also further treatment methods like anodizing, electrostatic spraying, electrophoresis, PVDF coating, heat transfer printing etc. Various treatment methods enable aluminum alloy manufacturers provide products with richer color and designs. Third, aluminum coil is of better machinability. Owing to its weaker hardness, it’s easy to be bent, pressed and cut into any wanted shapes, thickness and designs, which greatly enlarges its application fields. Fourth, aluminum sheet is lighter than stainless steel. That means it’s easier to be transported and carried. When it comes to special usage like ceilings, which are suspended above heads, the former is a better choice. Fifth, both materials may go rust if not being processed and maintained carefully. Last but not least, aluminum coil sheet is cheaper. This advantage is undoubtedly overwhelming.

Combining the information above, we can see that aluminum alloy can not compete with stainless steel in only one part–hardness, but good workability and cheep price supply a gap. Therefore, under the same circumstances people would rather choose the former as raw material most of the time.

Nydia

Nydia

Sales Manager

Sales Manager