Aluminum coil a1100 h14 application

April 2, 2020

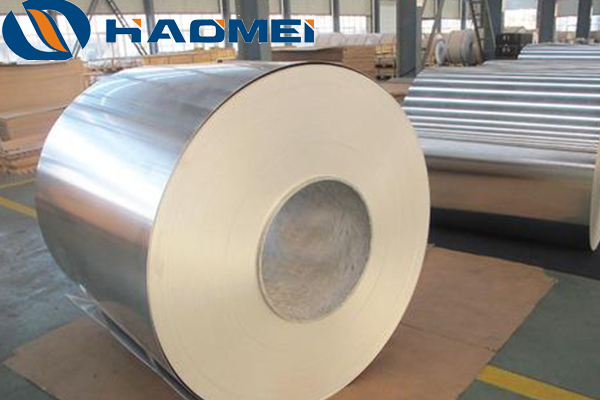

Aluminum coil a1100 h14 is technically pure aluminum containing 99% aluminum and 1% other metals. It is provided in the temper X14. In order to achieve this temper, the metal is hardened to a strength that is roughly halfway between the calcined (O) and full-hard (H18). Soft, ductile and workable, it’s ideal for applications including complex forming because it works harden more slowly than other alloys.

The first application of 1100 aluminum coil falls on heat sinks, for 1100 is featured by high elongation, good tensile strength, outstanding electricity conductivity and excellent forming property, suitable for processing methods for heat sinks like bending, pressing and forming. Owing to its distinguished elongation and forming ability, the coil can be rolled into thin sheet for printing boards and bottle caps. 1100 coil is not heat-curable, with excellent resistance to corrosion and widely used in chemical and food industries, too. In addition to bottle caps, it’s made into cookware as well, displaying better corrosion resistance and hardness than other members of 1xxx series. Further more, aluminum coil a1100 h14 responds well to decorative finishes. Regular decorative methods, such as mirror finish, anodizing, color coating, embossing and so on, works well on it. This enables people to apply the coil of varied finished to advertising, decoration and construction.

In spite of extensive application scope of 1100 h14 aluminium coil mentioned above, the scope is restricted in fields that require good corrosion resistance yet low hardness, as the coil ranks almost bottom in regard of hardness among aluminium alloys.

Nydia

Nydia

Sales Manager

Sales Manager