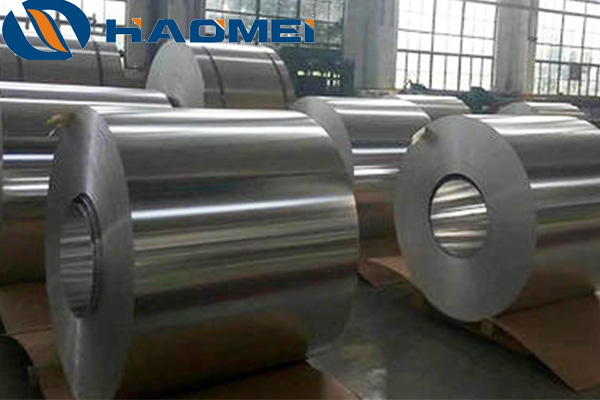

Aluminum coil 5052 h34

March 30, 2020

Aluminum coil 5052 h34 is of 2.72g/cm3 and 0.2mm to 8mm thick. As a typical aluminum magnesium alloy, it contains a small amount of manganese, chromium, beryllium, titanium, etc. Although a small amount of manganese dissolves, most of it forms mnal6. The effect of chromium in 5052 aluminium is similar to that of manganese: to improve the ability of stress corrosion cracking resistance, increase the strength of base metal and weld, and reduce the tendency of welding cracks, but the content of chromium is generally less than 0.35%. With an elongation larger than 80, 5052 aluminum coil is applied to aluminium checker plates, umbrella ribs, vehicle panels, plan oil tanks, ship sheet metal parts and so on.

General properties of 5052 h34 aluminum coil incorporates good corrosion resistance, excellent welding property, satisfying cold processing ability, medium hardness, high fatigue resistance, and poor machining ability. In detail, properties of the coil fall on three aspects: forming, welding and machining ability. First, the alloy has good plasticity in the hot process. The forging and die forging temperature is 420 ~ 475 ° C, and the deformation rate is more than 80% in this temperature range. The cold stamping performance of 5052 is related to the alloy state. The cold stamping performance in annealed (o) state is good, followed by H32 and H34 state, but not H36 / h38 state. Second, its properties of gas welding, arc welding, resistance welding, spot welding and seam welding of the alloy are good. The alloy performs well in brazing but poor in soldering. The weld is high in strength (90% ~ 95% of the strength of the base metal)and plasticity but poor in the air tightness. Third, The machinability of the alloy in annealed state is not good, but it is improved in cold work hardening state.

Nydia

Nydia

Sales Manager

Sales Manager