What is aluminium threshold strip

July 29, 2019

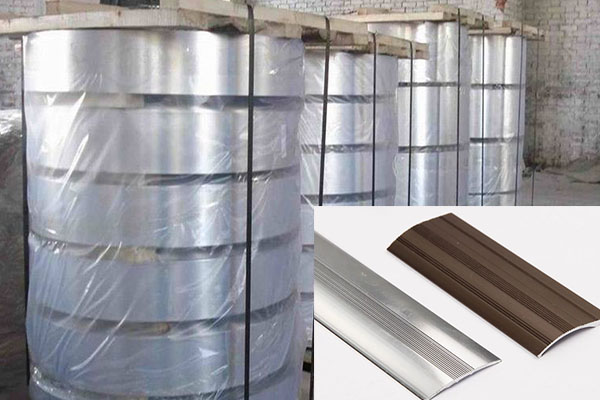

The aluminium threshold strip is not a type of aluminium strip rolls as some people might imagine. It is actually a kind of T bar extruded aluminum profile used as a threshold between two adjoining rooms.

Regular alloys for aluminium metal strips, such as 1060, 1070, 3003 and so on, are not suitable to be made into aluminium threshold strips, for these alloys are not strong enough. Harder alloys like 6061 and 6063 become better candidates. These alloys can be heat treated, which greatly improves their mechanical properties. T3, T5 and T6 are the most popular tempers. The strip surface can be coated with various designs and colors by a special anodizing or powder coating process. Possible colors of an aluminium threshold strip include silver, gold, champagne, bronze, green, blue, black, white ect, almost any color you need to match your decoration style. The specification of such a strip are featured by thickness and length. Generally the thickness is 0.4mm and above, and length 2.4m, 2.5m, 2.7m, 3.0m or longer.

An aluminium threshold strip is featured by good wear&corrosion resistance, comfortable smoothness, elegant outlook and easy installation. Good wear and corrosion resistance is a natural advantage of all aluminium products, including aluminium metal strips. The aluminium element is so active that it reacts quickly to oxygen in the air during which aluminium oxide comes into being and functions as a protective layer against most corrosive elements. In addition, good toughness make it possible to process aluminium into strips of necessary thickness and bend the strips into desired shapes. The surface of aluminium strip gives a natural luxurious metal gloss. After being processed by color coating, mirror finishing or anodizing, the surface becomes even more smooth and elegant, but it’s usually treated by these steps after necessary cutting and drilling have been made. Sometimes holes are needed to hold bolts and screws which connect the strip to a fixed object.

Nydia

Nydia

Sales Manager

Sales Manager