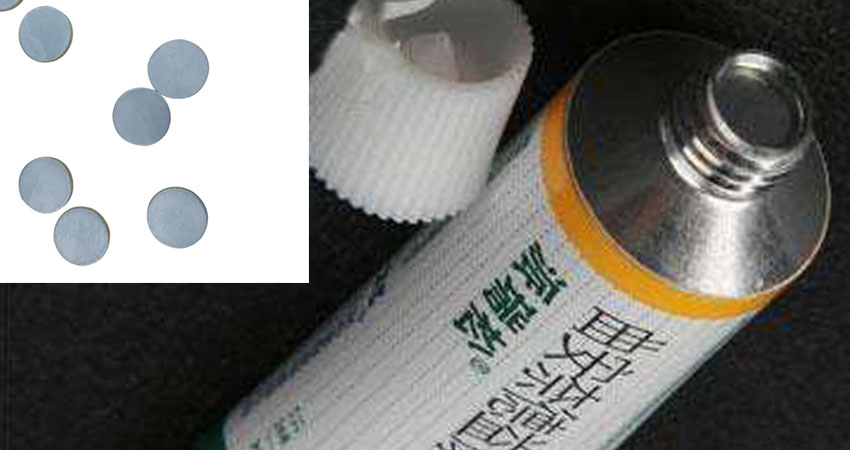

Aluminium Slugs Used for Unguent Tubes

August 8, 2018

Aluminium slugs refer to small aluminum particles in flat round, oval, cylinder etc. They are refined by repeated drawing, cutting and grinding processes of aluminum ingots containing 99% aluminum content, usually processed into surfaces of thin-walled pieces. Cylindrical aluminium slugs are widely used in the surface finishing of aluminum, copper and zinc castings, sandblasting and polishing of various metal surfaces as well as deburring, burr, surface of blade and sandblasting of casting products. The purpose is to improve flatness, brightness and whiteness of these products. In addition, the aluminum particles can be used together with stainless steel sand and stainless steel pellets to achieve a whiter and brighter surface on the surface of work-pieces. While flat and oval metal slug of aluminium slugs are usually used for containers and tubes in pharmaceutical and cosmetic industries. Unguent tubes are among the most popular applications.

Aluminium slugs are commonly made of 1070 aluminum, a type of industrial aluminum known for lower strength in comparison with other series. As the raw material for unguent tubes 1070 aluminium slug has appropriate strength. Unlike paper or plastic tubes, aluminum tubes do not break easily even under tearing, but they are relatively soft so that you can squeeze unguent out effortlessly. They are non-toxic and thus do not contaminate the unguent inside. In spite of high activity of the aluminum element, aluminium tubes can be treated by anodizing and color painting, which improves stability of the element. In addition, it’s easy to print designs and logos on the tubes. Last but not least, aluminium slugs cost less and have lighter weight. These factors make them perfect as unguent tube materials.

Nydia

Nydia

Sales Manager

Sales Manager