Aluminium Mirror Reflector Sheet Grade 1060 for Led Light

November 8, 2018

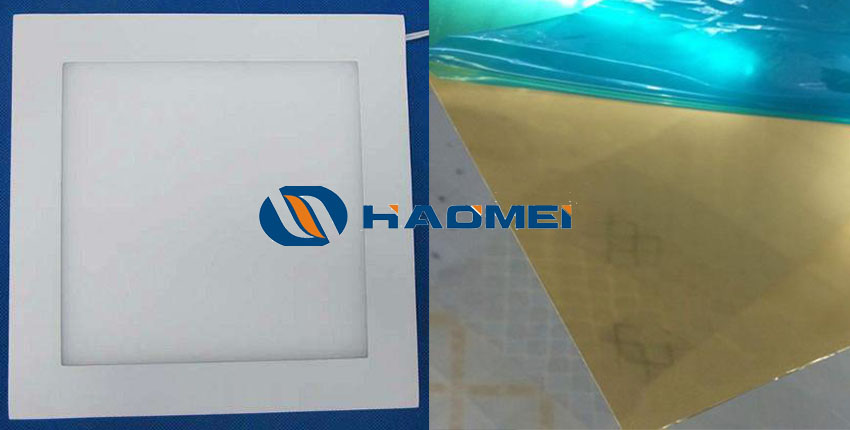

Aluminium mirror reflector sheet grade 1060 is a common material for the led light. 1060 aluminum sheet has a aluminium content of 99.6%, also referred to as a pure aluminum alloy whose content of aluminum reaches 99% and above. Pure aluminium is among the most frequently applied series. It has a great advantage in price over all other series, because it’s the earliest and most fully developed one of the industry. 1060 sheet has a good tensile strength, a satisfying extensive rate and high workability, meeting all regular requirements in further processing. It is usually applied to end products requiring low strength, such as sign panels, advertising boards, exterior decoration parts, vehicle body shells, wall decoration for tall buildings and factories, washing tanks, lamp holders, electric fan blades, electronic parts, chemical instruments, thin work-pieces, deep drawing or spinning utensils, welding parts, heat exchanging leaves, clock discs, nameplates, kitchen wares, ornaments, reflecting parts etc.

Aluminium mirror reflector sheet grade 1060 has high workability, corrosion resistance and conductivity. It can be used as the light reflector sheet. As an aluminium reflector sheet for lighting, 1060 polished sheet has an excellent reflectivity ranging from 85% to 95%. Generally this is enough as a reflector. Led lights usually consist of three parts: lamp panels, drive and shells. In addition to the drive which refers to electric wires, both the panel and shell can be made of 1060 aluminum mirror sheet. The lamp panel serves as a reflector and the shell as a heat sink. Heat sinks for led light must be made of metals of high heat conductivity. Metals with higher conductivity include silver, copper, aluminum and steel. Silver is too expensive. Copper has a conductivity almost doubling that of aluminium, but the latter proves to be much cheaper. Therefore, aluminium sheets are also a popular material for light heat sinks.

Nydia

Nydia

Sales Manager

Sales Manager